目 录

Pyrometry高温测量

1SCOPE 范围

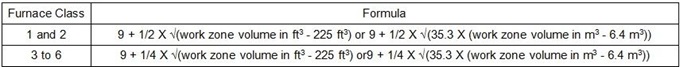

2 REFERENCES参照

2.1 Applicable Documents适用文件

2.2 Definitions定义

3TECHNICAL REQUIREMENTS技术要求

3.1 Temperature Sensors温度传感器

3.2 Instrumentation仪表化

3.3 Thermal Processing Equipment热处理设备

3.4 System Accuracy Test系统精度测试

3.5 Temperature Uniformity Surveys (TUS)温度均匀性测量

3.6 Laboratory Furnaces实验室炉

3.7 Records记录

3.8 Rounding修约

4QUALITY ASSURANCE PROVISIONS质量保证条款

5PREPARATION FOR DELIVERY交货准备

6 ACKNOWLEDGEMENT确认

7 REJECTIONS拒绝

8NOTES注释

AEROSPACE MATERIAL SPECIFICATION 航空航天工业材料规范

AMS2750™ REV. H Issued 1980-04 Revised 2024-07 Superseding AMS2750G

Pyrometry高温测量

AMS2750H results from a Two-Year Review and update of this specification with changes to Definitions (see 2.4.21, 2.4.25, 2.4.36, 2.4.47, and 2.4.84; General Sensor Requirements (see Table 3); Sensor Calibration (see 3.1.4.6 and Table 5); SAT and TUS Sensor Reuse (see 3.1.7.4 and 3.1.7.5); Base Metal Load Sensors (see 3.1.10.3); General instrumentation Requirements (see 3.2.1.4.1, 3.2.1.5, and Table 7); Control, Recording, and Over-Temperature instruments (see 3.2.3.4, 3.2.3.5, 3.2.3.16, and 3.2.3.18); instrumentation Calibration Results and Records (see 3.2.5.1); General instrument Correction and Modification Offset Requirements (see 3.2.6.1.2 and 3.2.6.1.8); Thermal Processing Equipment (see 3.3.7); General SAT Requirements (see Table 11, Table 12, and 3.4.1.2.1); Performing an SAT (see 3.4.2.2); Alternate SAT Frequency (see 3.4.8.3); SAT Waiver (see 3.4.9.6.3); SAT Difference Pass/Fail Requirements (see 3.4.10.4); Comparison SAT (see 3.4.11.1.e);Parts furnace class, instrument type, and TUS internal (see Table 15); Raw material furnace class, instrument type, and TUS internal (see Table 16); Initial TUS Temperatures (see 3.5.2.4); TUS Requirements for Batch Furnaces, Salt Baths, Controlled Temperature Liquid Baths and Fluidized Bed Furnaces (Excluding Controlled Temperature Quench Baths) (see Table 17); TUS Data Collection (see 3.5.10.1 and 3.5.10.2); Relocation of Hot or Cold Recording Sensors for Type A and C instrumentation (see 3.5.15.2): Radiation Survey (see 3.5.17, 3.5.17.1, and 3.5.17.2); TUS interval Deviations (see 3.5.18); Rounding (see 3.8); and Quality Assurance Provisions (see 4.2, 4.4, and Table 22). Deleted Zener Voltage Reference (was 3.5.87).

1、 Scope 范围

1.1 This specification covers pyrometric requirements for equipment used for the thermal processing of metallic materials. Specifically, it covers temperature sensors, instrumentation, thermal processing equipment, correction factors and instrument offsets, system accuracy tests, and temperature uniformity surveys. These are necessary to ensure that parts or raw materials are heat treated in accordance with the applicable specification(s).

本规范涵盖了用于金属材料热加工的设备的热测量要求。具体而言,它涵盖了温度传感器、仪表仪表、热处理设备、校正因子和仪表偏移、系统精度测试和温度均匀性测量。这些是必要的,以确保零件或原材料按照适用的规范进行热处理。

1.2 This specification may be used in other non-heat treating applications when specified.

如果有规定,本规范可用于其他非热处理应用。

1.3 This specification is not applicable to heating or to intermediate thermal processing unless otherwise specified.

除非另有规定,本规范不适用于加热或中间热处理。

1.4 This specification applies to laboratory furnaces to the extent specified in 3.6.

本规范在3.6规定的范围内适用于实验室熔炉。

2、 Applicable Documents 适用文件

The issue of the following documents in effect on the date of the purchase order form a part of this specification to the extent specified herein. The supplier may work to a subsequent revision of a document unless a specific document issue is specified. When the referenced document has been cancelled and no superseding document has been specified, the last published issue of that document shall apply.

在采购订单日期生效的下列文件在此规定的范围内构成本规范的一部分。供应商可以进行文件的后续修订,除非规定了具体的文件问题。当被引用的文件被取消且没有指定替代文件时,该文件的最后一次发布应适用。

2.1 SAE Publications出版物

Available from SAE International, 400 Commonwealth Drive, Warrendale, PA 15096-0001, Tel: 877-606-7323 (inside USA and Canada) or +1 724-776-4970 (outside USA), www.sae.org.

AS7766 Terms Used in Aerospace Metals Specifications航空航天金属规范条款

2.2 ASTM Publications出版物

Available from ASTM International, 100 Barr Harbor Drive, P.O. Box C700, West Conshohocken, PA 19428-2959,Tel: 610-832-9585, www.astm.org.

ASTM E29 Using Significant Digits in Test Data to Determine Conformance with Specifications在测试数据中使用有效数字来确定与规范的一致性

ASTM E207 Standard Test Method for Thermal EMF Test of Single Thermoelement Materials by Comparison with a Reference Thermoelement of Similar EMF-Temperature Properties通过与具有相似电动势温度特性的参考热敏元件的比较对单个热敏元件进行热敏电动势试验的标准试验方法

ASTM E220 Calibration of Thermocouples by Comparison Techniques用比较技术校准热电偶

ASTM E230 Temperature-Electromotive Force (EMF) Tables for Standardized Thermocouples标准热电偶温度-电动势(EMF)表

ASTM E608 Mineral-Insulated, Metal-Sheathed Base Metal Thermocouples矿物绝缘,金属护套贱金属热电偶

ASTM E1137 Industrial Platinum Resistance Thermometers工业铂电阻温度计

ASTM E1751 Standard Guide for Temperature Electromotive Force (emf) Tables for Non-Letter Designated Thermocouple Combinations非字母指定热电偶组合的温度电动势(emf)表的标准指南

ASTM MNL7 Presentation of Data and Control Chart Analysis数据展示和控制图分析

ASTM MNL12 Use of Thermocouples in Temperature Measurement在温度测量中热电偶的使用

2.3 IEC Publications出版物

Available from IEC Central Office, 3, rue de Varembe, P.O. Box 131, CH-1211 Geneva 20, Switzerland,

Tel: +41 22 919 02 11, www.iec.ch.

IEC 60751 Industrial Platinum Resistance Thermometers and Platinum Temperature Sensors工业铂电阻温度计和铂温度传感器

ISO/IEC 17025 General Requirements for the Competence of Testing and Calibration Laboratories检测和校准实验室能力的一般要求

2.4 Definitions定义

Terms used in AMS2750 are defined in AS7766 and as follows:

AMS2750中使用的术语在AS7766中定义如下:

2.4.1 Accuracy精度/准确度

The maximum deviation of the instrument or sensor being tested from the values of a traceable standard. 被测仪表或传感器与可追溯标准值的最大偏差。

2.4.2 Adjustment调整

Any change to an instrument’s parameters仪表参数的任何改变。

2.4.3 Autoclave高压釜

An oven capable of operating at pressures higher than atmospheric pressure (nominally 760 mm Hg), commonly used in the processing of materials. It may be pressurized with steam, compressed air, or inert gas.

一种能在高于大气压的压力(名义上760毫米汞柱)下工作的烘箱,通常用于材料加工。它可以用蒸汽、压缩空气或惰性气体加压。

2.4.4 Base Metal Sensor廉金属传感器

Sensor whose thermoelements are composed primarily of base metals and their alloys. Examples of base metal sensors include Types E, J, K, N, M, and T.

热元件主要由廉金属及其合金组成的传感器。基本金属传感器的例子包括类型E, J, K, N, M和T。

2.4.5 Batch Furnace周期炉

A furnace where parts or raw materialare stationary during the soak.

在浸泡过程中零件或原材料静止的炉。

Note: Some batch furnaces may oscillate material within a stationary work zone.

注意:有些间歇炉可能会在固定的工作区域内使物料摆动。

2.4.6 Bias Or Input Shift偏倚或输入偏移

The act of making an adjustment to an instrument to add, remove, or alter an offset.

对仪表进行调整以增加、删除或改变偏移量的行为

2.4.7 Bimonthly两月一次

See Frequency看到频率

2.4.8 Biweekly两周一次

See Frequency看到频率

2.4.9 Calibration校准

An assessment of the accuracy of a sensor or an instrument to a traceable standard sensor and/or field test or standard instrument, based on one or more measurements, and potentially adjusting an instrument and/or compiling a deviation chart for a sensor or instrument in order to ensure compliance with requirements.

对传感器或仪表对可追踪的标准传感器和/或现场测试或标准仪表的精度的评估,基于一次或多次测量,并可能调整仪表和/或编制传感器或仪表的偏差图,以确保符合要求。

2.4.10 Continuous Furnace连续炉

A furnace where parts or raw material are conveyed continuously or semi-continuously from the charge area to the discharge area. Examples include: bump furnace, shaker furnace, belt furnace, roller furnace, and rotary hearth furnace.

一种连续或半连续地将零件或原料从上料区输送到下料区的炉子。包括鼓式炉、摇床炉、带式炉、辊式炉、转底炉。

2.4.11 Control Instrument控制仪表

An instrument connected to a control sensor used to control the temperature of thermal processing equipment. The instrument may or may not also record temperature data.

一种连接到控制传感器的仪表,用于控制热加工设备的温度。仪表可能也可能不记录温度数据

2.4.12 Control Sensor控制传感器

A sensor connected to a control instrument on thermal processing equipment, the temperature of which may or may not be recorded.

一种与热加工设备上的控制仪表相连的传感器,其温度可以记录也可以不记录。

2.4.13 Control Zone控制区

A portion of the working zone in thermal processing equipment having a separate sensor, instrument, and heating or cooling system to control its temperature. This portion of the thermal processing equipment is independently controlled.

热加工设备中工作区域的一部分,具有单独的传感器、仪表和加热或冷却系统来控制其温度。这部分热加工设备是独立控制的。

2.4.14 Controlled Temperature Liquid Bath控温液浴

A furnace containing a liquid that is heated to the desired heat treat temperature. Parts and raw material are normally immersed in the liquid.

一种包含液体的炉,该液体被加热到所需的热处理温度。零件和原料通常浸泡在液体中。

2.4.15 Controller控制器

A digital, or mechanical device that controls the temperature of thermal processing equipment (e.g., furnace control instruments, quench mechanical thermostat, freezer pressure controls, etc.).

一种控制热加工设备温度的数字或机械装置(如炉膛控制仪表、淬火机械恒温器、冷冻压力控制装置等)。

2.4.16 Correction Factor校正系数

The number of degrees, determined from the most recent calibration, that must be added to, or subtracted from, the temperature reading of a sensor, or an instrument, or a combination thereof (system) to obtain true temperature. The correction factors of sensors and instruments are usually kept separately and added together algebraically when a combination is used. Correction factor is the algebraic opposite of deviation (error)

在传感器、仪表或其组合(系统)的温度读数上加上或减去最近的校准值以获得真实温度的度数。传感器和仪表的校正系数通常分开保存,当使用组合时用代数法加在一起。修正因子是偏差(误差)的代数反义词。

2.4.17 Data Acquisition System数据采集系统

An instrument system used to automatically collect and store process data as an electronic record; for example, a Programmable Logic Controller (PLC).

一种用于自动收集和存储过程数据的电子记录的仪表系统,如可编程逻辑控制器(PLC)。

2.4.18 Deviation/Error偏离/误差

In the context of this specification, the difference between the uncorrected indicated temperature and the true temperature (Indicated temperature - True temperature = Deviation/error).

在本规范中,未校正的指示温度与真实温度之间的差值(指示温度-真实温度=偏差/误差)。

2.4.19 Digital Instrument数字式仪表

An instrument that records process measurements in a digital (numeric) display format or an instrument that prints both the scale (graph) and trend line simultaneously. Examples include recorders with pre-printed scales and printed tabular data meeting 3.2.1.4 data collection intervals and recorders that create scales and trend line or tabular data and also display indicated temperature.

一种以数字(数字)显示格式记录过程测量的仪表,或同时打印刻度(图形)和趋势线的仪表。例如:带有预打印刻度和打印表格数据的记录仪3.2.1.4数据收集间隔,以及创建刻度和趋势线或表格数据并显示指示温度的记录仪。

2.4.20 Electronic Record电子记录

Any combination of text, graphics, data, audio, pictorial, or other information representation in digital form that is created,modified, maintained, archived, retrieved, or distributed by a computer system.

由计算机系统以数字形式创建、修改、维护、归档、检索或分发的任何文本、图形、数据、音频、图形或其他信息表示形式的组合。

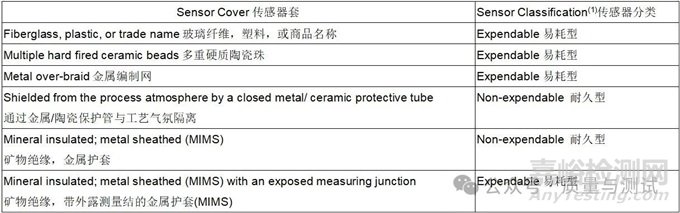

2.4.21 Expendable Sensors易耗型传感器

Sensors where any portion of the thermoelements are exposed to the thermal process equipment environment. Sensors with braided fiberglass insulation or plastic insulation are not designed to be inserted into a closed protection tube as the confined space causes drift when the additives (e.g., Teflon, color dies, and other chemicals) burn off. Therefore, these sensors are expendable even when installed into a closed protection tube.

热敏元件的任何部分暴露在热加工设备环境中的传感器。具有编织玻璃纤维绝缘或塑料绝缘的传感器不被设计为插入封闭的保护管,因为当添加剂(例如,特氟龙,色模和其他化学品)燃烧时,密闭空间会导致漂移。因此,即使安装在封闭的保护管中,这些传感器也是消耗性的。

2.4.22 Extension Wire延长导线

Wire used for transmitting an unmodified signal from the sensor to the instrumentation system. Wire is generally of the same sensor type, except for some sensor types that allow compensated extension wire.

用于从传感器向仪表系统传送未经修改的信号的导线。电线通常是相同的传感器类型,除了一些传感器类型允许补偿延长线。

2.4.23 Field Test Instrument现场测试仪表

An instrument meeting the requirements of Table 7 that has calibration traceable to a secondary standard instrument or better and is used to conduct on-site calibrations or tests of thermal processing equipment.

一种符合表7要求,校准可溯源至二级标准仪表或以上,用于对热加工设备进行现场校准或测试的仪表。

2.4.24 Fluidized Bed Furnace流态床炉

A furnace that contains a medium that becomes suspended or fluidized due to atmosphere gas or products of combustion passing upward through the medium. Parts and raw material are normally immersed in the fluidized medium.

由于大气气体或燃烧产物向上通过介质而使介质悬浮或流化的熔炉。零件和原料通常浸泡在流态化介质中。

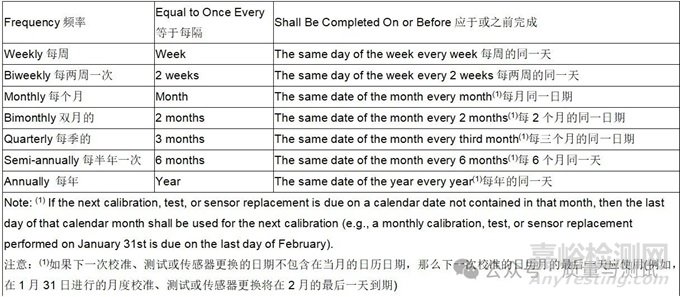

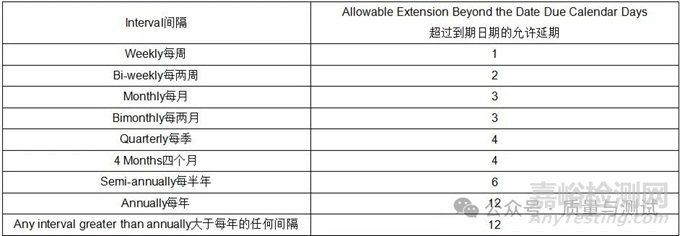

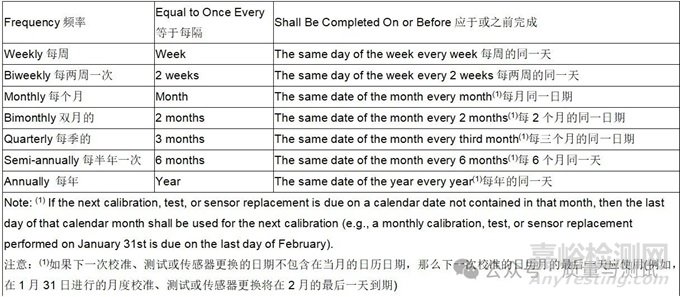

2.4.25 Frequency (Interval)频率(间隔)

The calendar days from the day/date a calibrations, tests, or sensor replacement was performed and the next day/date a calibration, test, or sensor replacement is due (inclusive). In the context of this specification, the following shall apply:

从执行校准、测试或传感器更换之日/日期起的日历天,到下一个校准、测试或传感器更换之日/日期(含)。在本规范的范围内,应适用以下规定:

2.4.26 Furnace炉子

Equipment used for the thermal processing of parts or raw material. The terms “furnace” and “oven” can be used interchangeably用于零件或原材料热加工的设备。炉子和烘箱这两个术语可以互换使用。

2.4.27 Heat Sink测温试块

A mass of material with an embedded sensor or sensors which supplies temperature data of that mass to recording instruments一块材料嵌入一个或多个传感器,可向记录仪提供温度数据。

2.4.28 Interval间隔

See Frequency见频率

2.4.29 Laboratory Thermal Processing Equipment实验室热加工设备

Equipment used exclusively for thermal processing of samples, specimens, or test parts as required by materials and processing specifications.

据材料和加工规范的要求,专用于试样、试样或试验件的热加工设备

2.4.30 Load Sensor载荷传感器

Sensor that is attached to, or in contact with, parts or raw material, a representation of parts or raw material, or is buried in the load of parts (e.g., fasteners) or raw material and which supplies temperature data of the parts or raw material to recording instruments that may be used to control the sequence of the production process, such as the start of soak.

附在工件或原材料上或与之接触的传感器,工件或原材料的表示,或埋藏在部件(如紧固件)或原材料的负载中,并向记录仪表提供工件或原材料的温度数据,记录仪表可能用于控制生产过程的顺序,如浸泡的开始。

2.4.31 Material Producer (Metallic)金属制品

The manufacturer of raw material as stated in 2.4.53原料制造商如2.4.53所述。

2.4.32 Maximum Permitted Error最大允许误差

A tolerance band for the thermal electric response expressed in degrees or percentages. Maximum permitted error provides a tolerance within which various types of sensors shall conform to standard sensor reference tables, or equivalent.

用度数或百分比表示的热电响应的容限。最大允许误差提供了一个公差,在此范围内各种类型的传感器应符合标准传感器参考表,或等效。

2.4.33 Measuring Junction测量接点

The location of a sensor where the wire elements are joined together to complete a measurement circuit, which is used to measure an unknown temperature. Also called the “hot junction”.

一个传感器的位置,在那里电线元件连接在一起,以完成一个测量电路,用来测量一个未知的温度。也叫热接点。

2.4.34 Multiple Zoned Furnaces多个分区炉

Furnaces with multiple separate temperature control zones. 具有多个独立温度控制区域的熔炉。

2.4.35 Noble Metal Sensor贵金属传感器

Sensor whose thermoelements are composed primarily of noble metals (e.g., platinum/platinum-rhodium) and their alloys. Examples of noble metal sensors include Types R, S, B, and RTDs.

热敏元件主要由贵金属(如铂/铂铑)及其合金组成的传感器。贵金属传感器的例子包括类型R, S, B和RTD。

2.4.36 Nonexpendable Sensors耐久型传感器

Sensors having no portion of the thermoelements exposed to the thermal process equipment environment. Sensors with ceramic insulators over bare wire inserted into a closed protection tube to prevent exposure to the thermal process equipment environment are considered nonexpendable sensors.

传感器的热敏元件部分不暴露在热处理设备环境中。

陶瓷绝缘体在裸线上插入封闭的保护管以防止暴露在热处理设备环境中的传感器被认为是非消耗性传感器。

2.4.37 Non-Metallic Materials非金属材料

In the context of this specification, this term refers to the curing of composite or adhesive bonded assemblies that are typically processed in autoclaves, air ovens, or heated presses.

在本规范中,这个术语指的是复合材料或粘合剂粘合组件的固化,这些组件通常在高压釜、烘箱或加热压力机中加工。

2.4.38 Offset补偿

Any manual or electronic adjustment to an instrument made to alter either the desired set point or the displayed value of the instrument’s calculated temperature. Manufacturer specific terminology may also include “bias”, “input shift”, etc.

对仪表进行的任何手动或电子调整,以改变所需的设定点或仪表计算温度的显示值。制造商专用术语还可能包括偏置、输入偏移等

2.4.38.1 Correction Offset修正补偿

Manual or electronic adjustment of an instrument to compensate for known errors of the measurement system (instrument, extension wire/connectors, sensor) to make the system more accurate.

手动或电子调整仪表,以补偿测量系统的已知误差(仪表,延长线/连接器,传感器),使系统更准确。

2.4.38.2 Modification Offset修改补偿

Manual or electronic adjustment of an instrument to compensate for known conditions such as, but not limited to, a skewed TUS result or control thermocouple placement in a retort or muffle.

手动或电子调节仪表,以补偿已知条件,如(但不限于)弯曲的TUS结果或控制热电偶在蒸馏器或消声器的位置。

2.4.39 Oven烘箱

Equipment used for the thermal processing of materials and parts. The terms “oven” and “furnace” can be used interchangeably.

用于材料和零件热加工的设备。术语oven和furnace可以互换使用。

2.4.40 Over-Temperature Instrumentation超温测温仪表

An independent sensor and instrument combination installed in the thermal processing equipment that is used to detect any over-temperature occurrence and generate an alarm and/or cut back or shut down heat input. The purpose for this control is to protect parts or raw material and/or the thermal processing equipment from overheating. Integrated control/recording/over-temperature instruments are permitted provided it can be demonstrated that the over-temperature instrument/module of an integrated system is separated from the furnace control/recording system.

一个独立的传感器和仪表组合安装在热加工设备中,用于检测任何超温事件并产生报警和/或削减或关闭热输入。这种控制的目的是防止零件或原材料和/或热处理设备过热。允许集成控制/记录/超温仪表,只要能证明集成系统的超温仪表/模块与炉膛控制/记录系统分离。

2.4.41 Parts工件

Usually identified by a part number, produced from raw material in accordance with the requirements of an engineering drawing and are usually tested by non-destructive techniques only. Parts are heat treated, by or for a fabricator, in accordance with a drawing, purchase order, fabrication order, or heat-treat specification.

通常由零件编号标识,由原材料按照工程图纸的要求生产,通常只采用无损检测技术。根据图纸、采购订单、制造订单或热处理规范,由制造商或为其进行热处理。

NOTE: The cognizant engineering organization has the authority to assign the terms “parts” or “raw material.” 注:认可的工程组织有权指定术语“部件”或“原材料”

2.4.42 Preventive Maintenance Program or PM Program预防性维护计划或PM计划

A program for evaluating, taking corrective action as required, and documenting the condition of items that have potential to adversely affect thermal processing equipment conformance to any requirement of this specification. Frequency of PM checks is established based on experience to ensure that no major problems occur between periodic PMs.

对可能对热加工设备符合本规范任何要求产生不利影响的项目进行评估、采取必要的纠正措施和记录的程序。根据经验建立PM检查的频率,以确保在定期PM之间不发生重大问题。

2.2.43 Primary Standard Instrument一级标准器

An instrument that is calibrated directly against a reference standard instrument and meeting the requirements of Table 7接对照参考标准仪表进行校正并符合表7要求的仪表。

2.4.44 Primary Standard Sensor一级标准传感器

Sensor calibrated directly against a reference standard and meeting the requirements of Table 1.

根据参考标准直接校准的传感器,并满足表1的要求。

2.4.45 Process Chart Recorder流程图表记录器

See Recording Instrument见记录仪表

2.4.46 Programmable Logic Controller (PLC)可编程控制器

A digital computer control system that continuously monitors the state of input devices and makes decisions based upon a programmed input (recipe) to control the state of output devices.

一种数字计算机控制系统,它不断地监视输入设备的状态,并根据程序输入(配方)作出决定来控制输出设备的状态。

2.4.47 Qualified Operating Temperature Range合格的工作温度范围

The nominal set point temperature range of thermal processing equipment where temperature uniformity has been tested within a qualified work zone and foundto be compliant with required tolerances (i.e., qualified operating temperature range = nominal range of TUS set points).

热加工设备的标称设定点温度范围,在合格的工作区域内测试温度均匀性,并找到符合要求的公差(即合格的工作温度范围= TUS设定点的标称范围)。

2.4.48 Qualified Work Zone合格的工作区域

The portion of a thermal processing equipment volume where temperature variation conforms to the required uniformity tolerance within the qualified operating temperature range as defined by the placement of sensors during the most recent temperature uniformity survey.

在最近的温度均匀性调查中,传感器的放置确定了合格的工作温度范围内,温度变化符合所需均匀性公差的热加工设备体积的一部分

2.4.49 Quality Organization Approval质量组织批准

Objective evidence of review and acceptance or rejection of a calibration or test as defined by a documented process within the user’s quality system which also defines any delegation of this approval.

用户质量体系文件化过程中定义的对校准或测试的评审、接受或拒绝的客观证据,也定义了该批准的任何授权

2.4.50 Quench System淬火系统

A system that provides rapid cooling, usually accomplished using oil, water, water/polymer mixtures, or gaseous mediums.

一种提供快速冷却的系统,通常使用油、水、水/聚合物混合物或气体介质。

2.4.51 Radiation Survey辐射测量

Initial survey of aluminum alloy thermal processing equipment used above 800 ℉ or 427 ℃ when the heat source (e.g., electrical elements or gas tubes) is exposed to the qualified work zone or only separated by a metal baffle.

当热源(如电气元件或气管)暴露在合格的工作区域或仅用金属挡板隔开时,对使用在800℉或427℃以上的铝合金热加工设备的初步测量。

2.4.52 Radiation Survey Sensor辐射测量传感器

A TUS sensor, typically base metal (Types E, J, K, N, M, and T) sensor, used in conjunction with a test panel for determining the heating characteristics of furnaces used for solution heat treating aluminum alloys.

TUS传感器,通常为贱金属(E、J、K、N、M和T型)传感器,与测试板一起用于确定铝合金固溶热处理炉的加热特性。

2.4.53 Raw Material原料

Usually includes, but is not limited to, such items as sheet, plate, wire, rod, bar, forgings, castings, and extrusions. Raw material is usually identified by a heat or lot number and is usually tested destructively for acceptance. Raw material is heat treated, by or for a material producer, in accordance with a process or material specification.

通常包括但不限于:薄板、板材、线材、棒材、棒材、锻件、铸件和挤压件。原材料通常通过熔炼号或批号来识别,通常在验收前进行破坏性测试。原料由原料生产商按照工艺或材料规范进行热处理。

NOTE: The cognizant engineering organization has the authority to assign the terms “parts” or “raw material.”

注:认可的工程组织有权指定术语“部件”或“原材料”

2.4.54 Raw Material Furnaces原材料炉

Equipment used in accordance with a process or material specification to process raw material.

按照工艺或材料规范加工原材料的设备。

2.2.55 Recording Instrument记录仪表

An instrument connected to a controlling, load and/or recording sensor that documents process equipment temperature data and generates a permanent process record. Examples are a chart recorder, electronic data recorder, or a data acquisition system.

一种连接到控制、负载和/或记录传感器的仪表,它记录工艺设备的温度数据,并产生永久的工艺记录。例如海图记录器、电子数据记录器或数据采集系统。

2.4.56 Recording Sensor记录传感器

A sensor that is connected to a recording instrument or connected to a control instrument of an integrated control/recording system.

连接到记录仪表或连接到综合控制/记录系统的控制仪表的传感器

2.4.57 Recurrent Temperature Pattern周期性的温度模式

Cycling of furnace temperature due to operation of the temperature control instrument.

由于温度控制仪表的操作,炉温的循环。

2.4.58 Reference Standard Instrument参考标准仪表

A standard test instrument that has been calibrated by NIST or other internationally recognized standards organization meeting Table 7 requirements.

由NIST或其他国际认可的标准组织校准的符合表7要求的标准测试仪表。

2.4.59 Reference Standard Sensor (Noble Metal)参考标准传感器(贵金属)

A noble metal standard sensor that has been calibrated by NIST or other internationally recognized standards organization meeting Table 1 requirements.

一种贵金属标准传感器,已由NIST或其他国际公认的标准组织校准,符合表1的要求。

2.4.60 Refractory Sensor耐火材料的传感器

A sensor whose thermoelements are composed primarily of refractory metals (e.g., Tungsten, Rhenium, Tantalum, Niobium,and Molybdenum) and their alloys. Example: Type C sensors.

一种热敏元件主要由难熔金属(如钨、铼、钽、铌和钼)及其合金组成的传感器。例如C型传感器。

2.4.61 Refrigeration Equipment冷处理设备

A compartment, cabinet, or room that may be held below room temperature and >32 ℉ or 0 ℃ (refrigerator), or ≤32 ℉ or 0 ℃ (freezer) depending on the temperature range of use. This equipment may be used for retarding or advancing metallurgical transformation or for storage of metallic materials. 一种隔间、柜子或房间,根据使用的温度范围,它可以保持在室温以下,温度为32℉或0℃(冰箱),或≤32℉或0℃(冷冻柜)。该设备可用于延缓或推进冶金转化,或用于金属材料的储存。

2.4.62 Resident SAT Sensor常驻SAT传感器

A test sensor that remains resident in the test location between system accuracy tests.

在系统精度测试之间保持在测试位置的测试传感器

2.2.63 Resistance Temperature Device (RTD)电阻温度装置

A device (for example, PT100, PRT, etc.) that produces a change in resistance across an element in response to the temperature at the element (usually in the tip).

一种器件(如PT100、PRT等),它能根据元件(通常在尖端)的温度在整个元件上产生电阻变化。

2.4.64 Retort Furnace马弗炉

A furnace that contains a retort or muffle which isolates the parts or raw material being heat treated from the heating elements. The furnace normally surrounds the retort.

一种含有蒸馏器或马弗的熔炉,它将被热处理的部件或原料与加热元件隔离开来。熔炉通常包围着蒸馏器。

2.4.65 Salt Bath盐浴

A furnace containing molten salt that is heated to the desired heat-treat temperature. Parts or raw material are normally immersed in the molten salt.

一种含有熔盐的熔炉,被加热到所需的热处理温度。零件或原料通常浸泡在熔盐中。

2.4.66 Secondary Standard Test Instrument二级标准测试仪表

An instrument calibrated directly against a primary standard or reference standard meeting Table 7 requirements and which is operated in a controlled test environment.

一种在受控的测试环境中操作的,直接根据主要标准或参考标准进行校准的仪表,符合表7的要求。

2.4.67 Secondary Standard Test Sensor二级标准测试传感器

A sensor calibrated directly against a primary standard test sensor, meeting the requirements of Table 1.

传感器直接校准的主要标准测试传感器,满足表1的要求。

2.4.68 Semi-Continuous Furnace半连续的炉子

See continuous furnace见连续炉

2.4.69 Sensor Or Temperature Sensor传感器或温度传感器

In the context of this specification, a device designed to detect or measure temperature (e.g., thermocouple, RTD, etc.).

在本规范中,用于检测或测量温度的设备(如热电偶、RTD等)。

2.4.70 Special Limits Of Error Sensor Wire特殊误差传感器线限

Sensors and extension wires whose initial calibration accuracy meets or exceeds the requirements of ASTM E230, Tables 2 and 3 for special tolerances.

初始校准精度满足或超过ASTM E230表2和表3特殊公差要求的传感器和延长线。

2.4.71 Stabilization稳定化(Also Referred To As Equalization, Equilibrium, Steady State, Or Soaked Condition也指均衡、平衡、稳态或浸泡状态)

Equipment stabilization occurs when all control and recording sensors are within the allowable temperature uniformity survey tolerance span and controllers are cycling and/or maintaining the desired temperature in each zone. Temperature uniformity survey stabilization occurs when all temperature uniformity survey sensors have reached the desired uniformity range and are not exhibiting a continual upward or downward trend away from the set point during and after the stabilized period of the temperature uniformity survey.

当所有控制和记录传感器都在允许的温度均匀性测量公差范围内,并且控制器在每个区域循环和/或保持所需的温度时,设备就会稳定。当所有温度均匀性测量传感器达到所需的均匀性范围,并且在温度均匀性测量的稳定期内和之后没有表现出从设定点持续上升或下降的趋势时,温度均匀性测量稳定发生。

2.4.72 System Accuracy Test (SAT)系统精度校验

An assessment of the sum of the combined errors or correction factors of the sensor, extension wire (and connectors), and instrument to ensure compliance with Table 11 or 12 requirements.

对传感器、延长线(和连接器)和仪表的综合误差或校正系数进行总和评估,以确保符合表11或12的要求。

2.4.72.1 Comparison SAT比对SAT

An assessment by comparison of the difference between the readings of the thermal process equipment sensor system being tested (sensor, extension wire, and instrument) and the corrected reading of the test sensor system (test sensor, extension wire, and field test instrument) after test sensor and field test instrument correction factors are applied (see 3.4.7). Also referred to as a “probe check.”

应用测试传感器和现场测试仪表校正因子后,通过比较被测试的热工艺设备传感器系统(传感器、延长线和仪表)的读数与测试传感器系统(测试传感器、延长线和现场测试仪表)的校正读数之间的差异来评估(见3.4.7)。也称为“探查检查”。

2.4.72.2 Alternate SAT替代SAT

A mathematical assessment of the sum of the errors or correction factors of the thermal processing equipment sensor and the calibration error or correction factor of the connector, extension wire, and instrument channel (see 3.4.8).

对热加工设备传感器的误差或修正系数和连接器、延长线和仪表通道的校准误差或修正系数之和的数学评估(见3.4.8)。

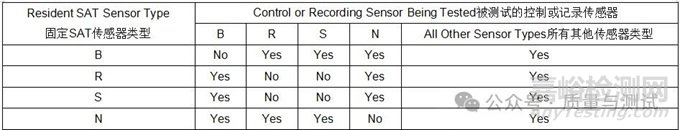

2.4.72.3 SAT Waiver豁免SAT

Additional requirements and comparisons to be made when the comparison or alternate SAT methods are not performed (see 3.4.9).

当不进行比较或备用SAT方法时,需要进行额外的要求和比较(见3.4.9)。

2.4.73 System Accuracy Test Sensor系统精度测试传感器

A calibrated and traceable sensor meeting the requirements of Table 1 used for an SAT

用于SAT的校准和可追踪传感器,满足表1的要求

2.4.74 Temperature Overshoot温度超调

When any temperature sensor exceeds the upper temperature tolerance as defined by the applicable thermal processing equipment class as stated in Table 8.

当任何温度传感器超过表8中所述的适用热加工设备类别所定义的最高温度公差时。

2.4.75 Temperature Sensor Pass-Through温度传感器直通

Installed wiring connecting sensors (typically thermocouples) inside the thermal processing equipment to the instrumentation outside, usually with sockets, jacks, or terminals at each end.

在热加工设备内部安装连接传感器(通常是热电偶)到外部仪表的接线,每一端通常有插座、插孔或端子。

2.4.76 Temperature Uniformity温度均匀性

The temperature variation (usually expressed as ± degrees) within the qualified work zone with respect to set point temperature. For retort furnaces where a sensor in the retort is used to control temperature, the temperature variation is with respect to the sensor in the retort and not to the furnace set point temperature. The requirement is established by the required thermal processing equipment class in accordance with Table 8.

合格工作区域内相对于设定值温度的温度变化(通常用±度表示)。对于蒸馏炉,在蒸馏炉中使用传感器来控制温度,温度变化是相对于蒸馏炉中的传感器而不是炉设定点温度。该要求根据表8所要求的热处理设备类别确定。

2.4.77 Temperature Uniformity Recorder温度均匀性记录器

Independent digital recording instrument meeting the requirements of Table 7 for a field test Instrument and used to perform temperature uniformity surveys.

独立数字记录仪表,满足表7对现场测试仪表的要求,用于进行温度均匀性测量。

2.4.78 Temperature Uniformity Sensor温度均匀性传感器

A calibrated and traceable sensor meeting the requirements of Table 1.

校准可追溯的传感器满足表1的要求。

2.4.79 Temperature Uniformity Survey (TUS)温度均匀性测量

An assessment of the temperature variation within the qualified work zone of thermal processing equipment prior to and after stabilization using a field test instrument (TUS recorder) meeting Table 7 requirements and sensors meeting the requirements of Tables 1, 17, and 18, as applicable.

使用满足表7要求的现场测试仪表(TUS记录仪)和满足表1、17和18要求的传感器(视情况而定),对热处理设备的合格工作区域稳定前后的温度变化进行评估。

2.4.80 Thermal Processing热处理

Any process in which parts or raw material are exposed to controlled heating, soaking, or cooling to achieve the specified properties or condition of the parts or raw material for which there is no exception in accordance with 1.3.

对零件或原材料进行受控加热、浸泡或冷却,以达到零件或原材料的特定性能或条件的任何工艺过程,无一例外地符合1.3的要求。

2.4.81 Thermal Processing Equipment热处理设备

A term used to refer to any vessel (such as autoclave, furnace, oven, quench and refrigeration equipment, liquid bath, heated press, etc.) used to process parts or raw material at controlled temperatures.

用于在控制温度下加工零件或原料的任何容器(如高压釜、熔炉、烘箱、淬火和制冷设备、液浴、加热压力机等)。

2.4.82 Thermocouple热电偶

A temperature sensor consisting of two wires (thermoelements) of dissimilar thermoelectric characteristics connected at a measuring junction. An EMF is developed between the two junctions in proportion to the temperature gradient.

由两根热电特性不同的导线(热电元件)组成的温度传感器连接在一个测量节点上,在两个节点之间根据温度梯度的比例形成电动势。

2.4.83 Traceable Or Traceability可追踪的或可追溯性

The ability to relate measurement results through an unbroken chain traceable to the International System of Units (SI) through internationally recognized standards organizations such as, but not limited to:

通过可溯源到国际单位制(SI)的不间断链,通过国际公认的标准组织,如但不限于:

National Institute of Standards and Technology (NIST) 国家标准与技术研究所(NIST)

National Physical Laboratory (NPL) 国家物理实验室

Physikalisch-Technische Bundesanstalt (PTB)

Swedish National Authority for Testing, Inspection, and Metrology瑞典国家测试、检验和计量管理局

China National Calibration Technology Specification (CNAS)中国国家校准技术规范

National Institute of Advanced Industrial Science and Technology (AIST)国立先进工业科学技术研究所

Instituto Nacional de Metrologia, Normalização e Qualidade Industrial (INMETRO)国立计量学会

Bureau International des Poids et Mesures (BIPM)国际测量局

2.4.84 Use (Of A Sensor) (传感器的)使用

One cycle of heating or cooling upon the sensor being placed into service (see Table 5 note 5, 3.1.4.2, 3.1.7.2, 3.1.7.5, and 3.1.11.1).

传感器投入使用后的一个加热或冷却周期(见表5注5、3.1.4.2、3.1.7.2、3.1.7.5和3.1.11.1)。

2.4.85 Vacuum Furnace真空炉

A furnace that processes parts or raw material at any pressure lower than atmospheric pressure (nominally 760 mm Hg) during soak.

在浸泡过程中,在低于大气压力(名义上760毫米汞柱)的任何压力下加工零件或原材料的炉

2.4.86 Wireless Transmitter无线传输器

A device for sending electromagnetic waves; the part of a broadcasting apparatus that generates and modulates the radio frequency current and conveys it to a receiver.

发射电磁波的装置;广播设备中产生和调制射频电流并将其传送给接收器的部分

3 Technical Requirements技术要求

3.1 Temperature Sensors温度传感器

3.1.1 General Sensor Requirements传感器的一般要求

3.1.1.1 Unless specifically noted, the requirements defined in this specification shall apply to all sensors.

除非特别注明,本规范中定义的要求应适用于所有传感器。

3.1.1.2 All sensors shall comply with the requirements of Table 1. Other sensors that possess equal or better calibration accuracy may be used. Thermocouple composition shall comply with the requirements of ASTM E230 or ASTM E1751, and Table 2.

所有传感器应符合表1的要求。可以使用具有相同或更高精度的其他温度传感器。热电偶成分应符合ASTM E230或ASTM E1751和表2的要求。

3.1.1.3 Resistance temperature devices (RTDs) shall be noble metal, shall comply with the requirements of Table 1, and shall be considered non-expendable.

电阻温度器件(RTD)应为贵金属,应符合表1的要求,并应视为非易耗品。

3.1.1.4 Sensors may be made either from bare or coated wire, or mineral insulated/metal sheathed (MIMS) cable as described in Tables 2 and 3.

传感器可以由裸线或包覆线,或矿物绝缘/金属护套(MIMS)电缆制成,如表2和3所示。

3.1.1.5 Measuring junctions shall be made by either of the following methods:

测量连接应采用下列任一方法:

• Any combination of twisting and/or welding the thermoelements provided there is no addition of filler metal (including ungrounded and grounded MIMS).

在不添加填充金属的情况下,对热敏元件进行任何扭转和/或焊接的组合(包括未接地和已接地的MIMS)。

• Spot welding the thermoelements directly to a part, simulated part, or heat sink is permitted for temperatures ≤2000 ℉ or 1100 ℃

在温度≤2000℉或1100℃时,允许将热元件直接点焊到零件、模拟零件或散热器上.

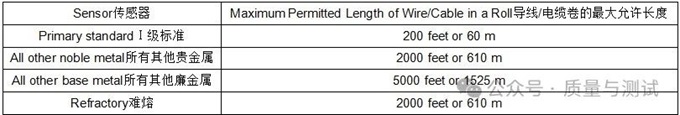

Table 1 - Sensors and sensor calibration传感器和传感器校准(12)

(1)Sensors of equal or better calibration accuracy are acceptable可接受同等或更高校准精度的传感器。

(2) Percent of reading or correction factor in ℉ or ℃, whichever is greater读数的百分数或修正值(以℃表示),取较大者。

(3) Sensor recalibration and reuse requirements are provided in Table 5 传感器再校准和复用要求见表5。

(4) NIST or other internationally recognized standards organization NIST或其他国际公认的标准组织。

(5) A reference standard sensor together with a primary standard instrument shall be used to calibrate primary standard sensors 一个参考标准传感器和一个Ⅰ级标准仪表应用于校准Ⅰ级标准传感器。

(6) A primary standard sensor together with a primary standard instrument shall be used to calibrate secondary standard sensors一个Ⅰ级标准传感器和一个Ⅰ级标准仪表应用于校准Ⅱ级标准传感器。

(7) Use shall be limited to the calibration of control, recording and load sensors, SAT, and TUS sensors.

用于控制、记录和负载传感器、SAT和TUS传感器的校准。

(8) A primary or secondary standard sensor together with a primary or secondary standard instrument shall be used to calibrate these sensors 一个Ⅰ级或Ⅱ级标准传感器和一个Ⅰ级或Ⅱ级标准仪表用于校准控制、记录和负载传感器。

(9) For refractory sensors Type C: ±8.0 ℉ or ±4.4 ℃ or ±1%, the sensor correction factor shall be used for all applications C型耐久传感器:±4.4℃或±1%t,所有传感器修正值应使用。

(10) RTDs, when used, shall be platinum type and meet Class/grade A tolerances given in ASTM E1137 or IEC 60751. This does not apply to RTDs used in conjunction with a refrigeration equipment controller当使用RTD时,应是铂型,并满足ASTM E1137或IEC 60751中给出的A级公差。这不适用于与制冷设备控制器连接使用的RTD。

(11) For temperatures <32 ℉ or <0 ℃ for Types K, E, and T only, calibration accuracy shall meet the following:

仅对温度<0℃的K、E和T类型,校准精度应满足以下要求:

Type K: -328 to 32 ℉, ±4.0 ℉ or -200 to 0 ℃, ±2.2 ℃, or ±2.0 % for either, whichever is greater.

K型:-200~0℃,±2.2℃或±2.0%t,取较大者。

Type E (MIMS): -328 to 32 ℉, ±4.0 ℉ or -200 to 0 ℃, ±2.2 ℃, or ±2.0 % for either, whichever is greater.

E型(MIMS):-200~0℃,±2.2℃或±2.0%t,取较大者。

Type E (all other): -328 to 32 ℉, ±3.0 ℉ or -200 to 0 ℃, ±1.7 ℃, or ±1.0 % for either, whichever is greater.

E型(其他所有):-200~0℃,±1.7℃或±1.0%t,取较大者。

Type T: -328 to 32 ℉, ±1.8 ℉ or -200 to 0 ℃, ±1.0 ℃, or ±1.5 % for either, whichever is greater

T型:-200~0℃,±1.0℃或±1.5%t,取较大者。

(12) Sensors and sensor materials are normally supplied to meet the tolerances specified in the table for temperatures above 32 ℉ or 0 ℃. The same materials, however, may not fall within the tolerances for temperatures below 32 ℉ or 0 ℃. Two separate sensors may be required, one for each range.

传感器和传感器材料的供应通常满足表中规定的温度大于0℃的公差。然而,相同的材料可能不符合0℃以下的温度公差。可能需要2个单独的传感器,每个范围1个。

(13) When correction factors are used during production在生产中使用修正值时:

Type B sensors shall meet a calibration accuracy of ±0.5% B型传感器应满足±0.5%t的校准精度

Types R and S sensors shall meet calibration accuracy of ±2.7 ℉ or ±1.5 ℃ or ±0.25%, whichever is greater

R型和S型传感器应满足±1.5℃或±0.25%t的校准精度,取较大者。

Table 2 - Sensor and extension wire/connector传感器和延长导线/接头

(1) All color codes stated are in accordance with ASTM E230. Color codes in accordance with other internationally recognized standards organizations are acceptable.

所有颜色代码都符合ASTM E230。颜色编码按照其他国际公认的标准组织是可以接受的

(2) Most base metal extension wires have the same nominal composition as the sensor wires with which they are intended to be used, whereas the compensating extension wires for noble metal (Types S, R, and B) or refractory metal sensors (Type C) are usually of a different, more economical composition whose relative thermoelectric properties as a pair nonetheless closely approximate those of the noble metal or refractory metal sensors with which they are to be used over a limited temperature range.

多数有相同的名义成分的廉金属延长导线被连接传感器使用,而贵金属补偿导线(类型S, R, B)或难熔金属传感器(C型)通常是不同的,更为经济成分的相对热电性能仍然是一对密切近似的贵金属或难熔金属传感器,这是他们在有限的温度范围内使用。

(3) The designation “Type M” may not be recognized by all international standards. Type K extension wire and connectors shall be used for Type M sensors. “M型”并非所有国际标准都认可。K型补偿导线和连接器可用于M型传感器。

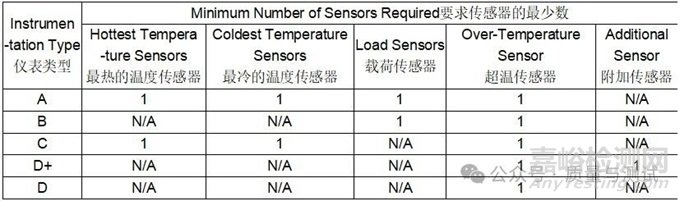

Table 3 - Sensor classification传感器分类

(1) See definitions for expendable and nonexpendable sensors见易耗型/耐久型传感器的定义。

3.1.2 Sensor Temperature Range of Use使用的传感器温度范围

Guidelines for sensor temperature range usage can be found in ASTM MNL12, ASTM E230, ASTM E608, ASTM E1137, ASTM E1751, IEC 60751, or other internationally recognized standard, and the sensor supplier.

传感器温度范围的使用指南可以在ASTM MNL12, ASTM E230, ASTM E608, ASTM E1137,ASTM E1751, IEC 60751或其他国际公认的标准和传感器供应商中找到。

3.1.3 Extension Wire and Connectors补偿导线及接头

3.1.3.1 Extension wire shall be of the same nominal composition as the sensor and instrumentation used, except when compatible compensating extension wire is allowed (e.g., noble metals). Extension wire shall meet the requirements of Table 2.

补偿导线的名义成分应与所使用的传感器和仪表匹配,除非允许兼容的补偿导线(例如,贵金属)。补偿导线应满足表2的要求。

3.1.3.2 Extension wire shall not be spliced other than using a compatible connector.

除使用兼容连接器外,补偿导线不得拼接。

3.1.3.3 Connectors, plugs, jacks, and terminal strips are permitted if they are the compatible type, i.e., they have thermoelectric properties conforming to the characteristics of the corresponding sensor type.

如果连接器、插头、插座和端子片是兼容类型,即它们的热电性能符合相应传感器类型的特性,则是允许的。

3.1.3.4 Wireless transmitters may be used as an alternative to extension wire.

无线传送器可代替补偿导线。

3.1.4 Sensor Calibration传感器校准

3.1.4.1 The sensor calibration technique shall comply with ASTM E207 or ASTM E220, or other internationally recognized standards.

传感器校准技术应符合ASTM E207或ASTM E220或其他国际公认标准。

3.1.4.2 Sensors shall be calibrated before their first use.

传感器在首次使用前应进行校准。

3.1.4.3 Sensor calibration intervals whether based on time, number of uses, or temperatures, are the maximums permitted.

传感器校准周期,无论是基于时间,使用次数,或温度,允许最大。

3.1.4.4 Users shall have procedures that control the replacement of thermal process equipment sensors including limits on maximum life and/or number of uses based on supporting data such as, but not limited to, SAT, TUS, and re-calibration data, and/or trend analysis.

用户应有控制热加工设备传感器更换的程序,包括基于支持数据(如但不限于SAT、TUS和重新校准数据和/或趋势分析)的最大寿命和/或使用数量限制。

3.1.4.5 Sensors shall be calibrated or re-calibrated at or lower than the lowest temperature of use and at or higher than the highest temperature of use. Sensors used at a single temperature may be calibrated at the single temperature of use.

传感器应在低于最低使用温度和高于最高使用温度进行校准或重新校准。在单一温度下使用的传感器可以在使用的单一温度下校准。

3.1.4.6 Intervals between calibration or recalibration temperatures provided by the calibration agency shall not exceed 250 ℉ or 140 ℃ for all sensors. The fixed point calibration method in ASTM MNL12 or other internationally recognized standards may be used. No matter what standard is used, the calibration agency shall provide additional calibration points that do not exceed 250 ℉ or 140 ℃ for all sensors.

对所有传感器,校准机构提供的校准或重新校准温度间隔不应超过140℃。可采用ASTM MNL12或其他国际公认标准中的定点校准方法。无论使用何种标准,校准机构都应为所有传感器提供不超过250℉或140℃的额外校准点。

3.1.4.7 Extrapolation of calibration correction factors above the highest calibration temperature and below the lowest calibration temperature is prohibited by any calibration source except NIST or other internationally recognized standards organization.

除NIST或其他国际公认的标准组织外,任何校准禁止采用高于最高校准温度和低于最低校准温度校准修正值外推法。

3.1.4.8 Interpolation of correction factors between two known calibration points is permitted using the linear method.

允许使用线性方法在两个已知校准点之间插入修正值。

3.1.4.9 Alternatively, the correction factor of the nearest calibration point shall be used.

或者,使用最近的校准点的修正值。

3.1.4.10 Whichever method is used shall be defined and applied consistently.

论使用哪种方法,都应一致地定义和应用。

3.1.4.11 For recalibration of sensors when permitted in Table 5, it is acceptable to use either the date of recalibration, or the date of first use following recalibration as the beginning of the calibration period. Procedures shall identify how the practice is applied and documented to ensure compliance.

对于表5中允许的传感器重新校准,可以使用重新校准日期或重新校准后首次使用的日期作为校准期的开始。程序应确定实际如何应用并形成文件,以确保符合性。

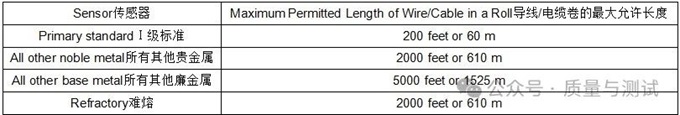

3.1.5 Wire/Cable Rolls导线/电缆卷

3.1.5.1 Calibrated expendable or non-expendable sensors made from rolls may be used in lieu of individually calibrated sensors.

由成卷的经过校准的易耗型或耐久型传感器可用来代替单独校准的传感器。

3.1.5.2 The maximum length of wire/cable in a roll at the time of calibration shall comply with Table 4.

校准时每卷电线/电缆的最大长度应符合表4。

Table 4 - Maximum permitted length of wire/cable in a roll电线/电缆卷的最大允许长度

3.1.5.3 Rolls shall be sampled and calibrated at both ends. The individual correction factors from each end shall be within the requirements of Table 1 and the average correction factor shall be calculated from both ends of the roll at each calibration temperature and used for the entire length of the roll.

丝卷在两端取样校准。每端的单个修正值应在表1的要求内,平均修正值应在每个校准温度下从丝卷的两端计算,并用于整个丝卷。

3.1.5.4 The roll shall not be used if the difference between the correction factors from each end of the sample sensors at any individual calibration temperature exceeds:

如果样品传感器在任何单个校准温度下两端的修正值之差优于:

a. 1.0 ℉ or 0.6 ℃ for primary and secondary standard sensors.

Ⅰ级和Ⅱ级标准传感器0.6℃。

b. 2.0 ℉ or 1.1 ℃ for control, recording, and load sensors, SAT, and TUS sensors.

控制、记录、负载传感器、SAT和TUS传感器1.1℃。

3.1.5.5 The following shall apply to rolls not meeting the requirements of 3.1.5.4:

对于不符合3.1.5.4要求的丝卷,应采取下列措施:

a. It is permitted to divide the roll into shorter lengths provided the shorter lengths meet the requirements of 3.1.5.4.

只要丝卷的长度满足3.1.5.4的要求,就可以将丝卷分成较短长度的。

b. It is permitted to use individual sensors from the roll provided they are calibrated to the requirements of Table 1.

允许使用自丝卷的校准达到表1要求的单个传感器。

3.1.6 General Sensor Reuse Requirements一般传感器重复使用要求

Reuse of any sensor is not permitted unless the insulation remains intact and the wire/cable including the measuring junction are not damaged (see Table 5).

不允许重复使用任何传感器,除非绝缘保持完好,电线/电缆包括测量接点没有损坏(见表5)。

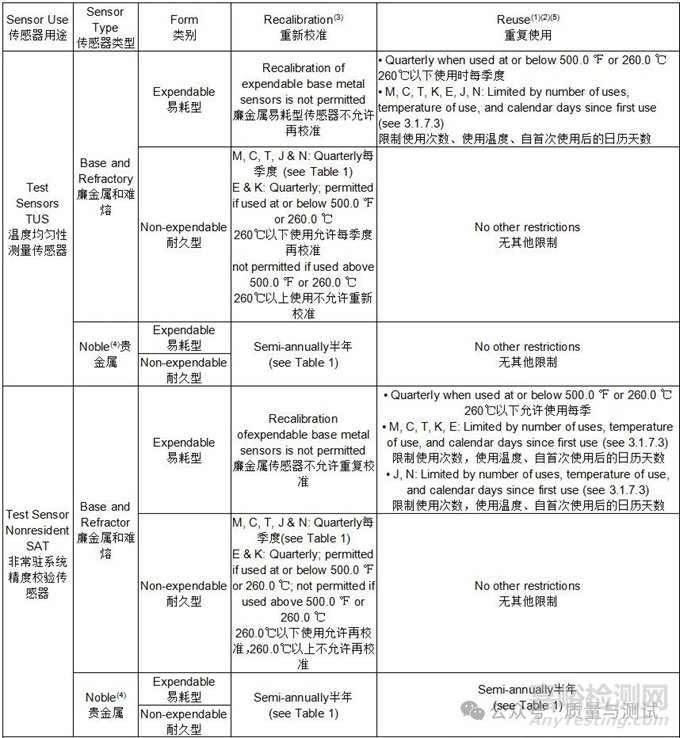

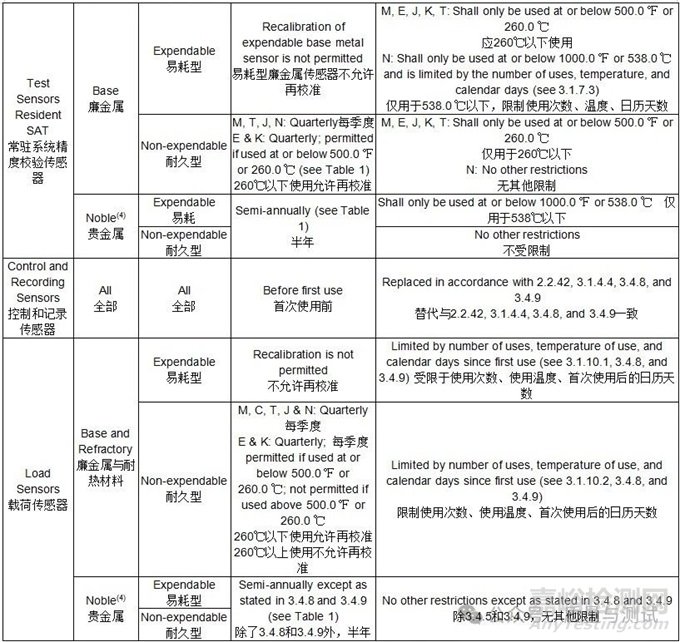

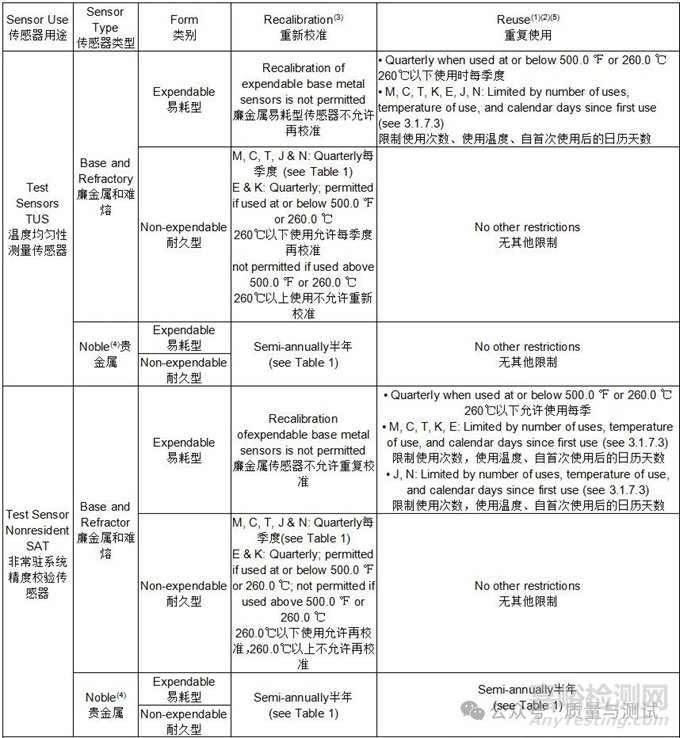

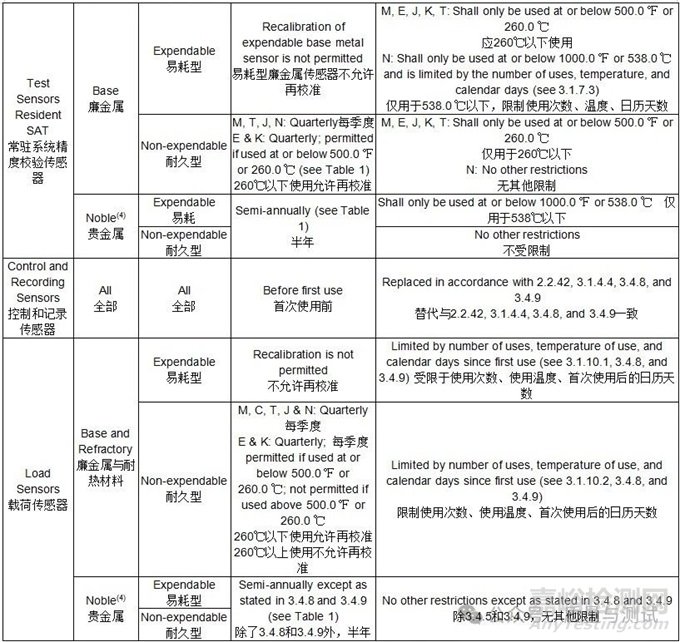

Table 5 - Sensor reuse and recalibration传感器重复使用和重新校准

Notes:

(1) For reuse of any Type E or K sensor used above 500.0 ℉ or 260.0 ℃, the depth of insertion shall be equal to or greater than any previous use (see 3.1.7.1).

对于在260.0℃以上重复使用的任何E型或K型传感器,插入深度应等于或大于任何以前的插入深度(见3.1.7.1)。

(2) See 3.1.6 and 3.1.7 for general reuse restrictions.

参见3.1.6和3.1.7一般重复使用限制条件。

(3) Recalibration of any Type E or K sensor used above 500.0 ℉ or 260.0 ℃ is prohibited.

禁止在260.0℃以上使用任何E型或K型传感器进行重新校准。

(4) Includes RTDs 包括RTD

(5) Reuses: Example 1: Begin at room temperature, ramp to 900 ℉ or 480 ℃ for first TUS temperature, then ramp to 1200 ℉ or 650 ℃ for TUS max temperature, then cool back to room temperature. This is a single use.

重复使用:示例1:从室温开始,第一个TUS温度上升到900 ℉或480℃,然后上升到1200 ℉或650 ℃的TUS最高温度,然后冷却回室温。这是一次使用。

Example 2: Begin at room temperature, ramp to 1325 ℉ or 718 ℃ for first production temperature, then cool to 1150 ℉ or 621 ℃ for the second production temperature, then cool back to room temperature. This is a single use.

例2:从室温开始,第一次生产温度上升到1325 ℉或718℃,然后冷却到1150 ℉或621 ℃,第二次生产温度,然后冷却回室温。这是一次使用。

Example 3: Begin at room temperature, ramp to 1900 ℉ or 1038 ℃ for first production temperature, then cool to 300 ℉ or 150 ℃, then ramp up to 1100 ℉ or 593 ℃ for second production temperature, then cool back to room temperature. This is two uses even if the load remained closed inside the equipment.

例3:从室温开始,第一次生产温度上升到1900℉或1038℃,然后冷却到300℉或150℃,然后上升到1100℉或593℃进行第二次生产温度,然后冷却回室温。这是两个用途,即使负载保持关闭在设备内。

3.1.7 SAT and TUS Sensor Reuse系统精度校验和温度均匀性测量传感器的重复使用

3.1.7.1 During the reuse of Type E or K sensors when used above 500.0 ℉ or 260.0 ℃, the depth of insertion shall be equal to or greater than any previous use.

对E型或K型传感器在260.0℃以上重复使用,其插入深度应等于或大于任何以前的插入深度。

3.1.7.2 Expendable base metal, noble metal, and refractory SAT and TUS sensors may be reused:

易耗型廉金属、贵金属和难熔SAT和TUS传感器可重复使用:

a. Base metal and refractory sensors may be used for up to 3 months from first use, without limit to number of uses, when used exclusively at or below 500.0 ℉ or 260.0 ℃.

当仅在260.0℃以下使用时,廉金属和难熔传感器可从首次使用起使用3个月,使用次数不限。

b. Noble metal sensors may be used for up to 6 months from first use, without limit to number of uses or temperature of use.

贵金属传感器从首次使用起可使用长达6个月,不限制使用次数或使用温度。

3.1.7.3 Expendable Base Metal and Refractory SAT and TUS Sensors:

易耗型廉金属和难熔系统精度校验和温度均匀性测量传感器:

a. Types M, C, T, K, and E shall be limited to 3 months or five uses, whichever occurs first, between 500.0 ℉ and 1200.0 ℉ or between 260.0 ℃ and 650.0 ℃, and limited to a single use above 1200.0 ℉ or 650.0 ℃.

M、C、T、K和E型应限制在260.0℃~650.0℃间使用3个月或5次,以先到为准,并限制在650.0℃以上的一次使用。

b. Types J and N shall be limited to 3 months or ten uses, whichever occurs first, between 500.0 ℉ and 1200.0 ℉ or between 260.0 ℃ and 650.0 ℃, and limited to a single use above 1200.0 ℉ or 650.0 ℃.

J型和N型应限制在260.0℃~650.0℃之间使用3个月或10次,以先到为准,且限制650.0℃以上的单次使用。

3.1.7.4 Records shall be maintained of the accumulated sensor reuse including sensor batch number, temperature, and use count.

应保持传感器累计重复使用的记录,包括传感器批号、温度和使用计数。

Example 1: Sensors are replaced after a single use. Sensor batch number shall be recorded for the SAT and/or TUS.

例1:传感器使用一次后更换。应记录SAT和/或TUS的传感器批号。

Example 2: Sensors are reused. Sensor batch number, temperature, and use count shall be recorded for each use.

例2:传感器被重用。每次使用时应记录传感器批号、温度和使用次数。

3.1.7.5 Base metal or refractory TUS sensors shall be limited to no more than the maximum number of uses defined in 3.1.7.3 for expendable sensors, 270 uses for nonexpendable sensors, or 6 months from first use, whichever occurs first, and may be reused subject to the limitations of 3.1.6 and 3.1.8 that are:

廉金属或难熔温度均匀性测量传感器的使用次数不得超过3.1.7.3中定义的易耗型传感器的最大使用次数,耐久型传感器的最大使用次数270,或首次使用后6个月(以先到为准),并可在符合3.1.6和3.1.8的限制条件下重复使用:

a. Used exclusively ≤1200 ℉ or ≤650 ℃, 仅用于≤650℃。

b. Identified by the date of installation and by the number and temperatures of accumulated uses, and根据安装日期和累计使用的次数和温度确定。

c. Preserved/protected from damage (i.e., crimping, excessive moisture contact, corrosion, etc.) between each TUS or remain installed on a rack that is protected between each TUS.

保存/保护每次温度均匀性测量间的损坏(例如,卷曲、接头过度潮湿、腐蚀等)或保持安装在一个支架上,每个温度均匀性测量间的保护。

3.1.8 Sensor Salvage传感器修复

3.1.8.1 Salvage of damaged expendable sensors is permitted if the discrepant portion including any portion previously exposed inside of the furnace is removed and the hot junction remade.

如果有差异的部分(包括以前暴露在炉内的任何部分)被移除并重新制作热接点,则允许修复损坏的易耗性传感器。

3.1.8.2 The salvaged sensor’s original calibration data shall be used.

修复传感器应使用原校准数据。

3.1.9 Control and Recording Sensors控制和记录传感器

3.1.9.1 Control sensors shall be positioned in thermal processing equipment to ensure control and maintain temperature uniformity of the equipment within the qualified work zone. Recording sensors shall be located in accordance with the applicable instrumentation type (see Table 9).

控制传感器应置于热加工设备中,以保证控制和保持设备在合格工作区的温度均匀性。记录传感器的位置应与适用的仪表类型匹配(见表9)。

3.1.10 Base Metal Load Sensors廉金属载荷传感器

3.1.10.1 Expendable base metal and refractory load sensors may be used:

易耗型廉金属和难熔载荷传感器可用于:

a. Up to 3 months after first use without limit to number of uses when used at or below 500.0 ℉ or 260.0 ℃.

当在260.0℃以下使用时,首次使用后3个月不受使用次数限制。

b. Types M, C, T, K, and E shall be limited to 3 months or five uses, whichever occurs first, between 500.0 ℉ and 1200.0 ℉ or between 260.0 ℃ and 650.0 ℃, and limited to a single use above 1200.0 ℉ or 650.0 ℃.

M、C、T、K和E型应限制在260.0℃~650.0℃间使用3个月或5次,以最先使用的为准,并限制在650.0℃以上使用一次。

c. Types J and N shall be limited to 3 months or ten uses, whichever occurs first, between 500.0 ℉ and 1200.0 ℉ or between 260.0 ℃ and 650.0 ℃, and limited to a single use above 1200.0 ℉ or 650.0 ℃.

J型和N型应限制在260.0℃~650.0℃间使用3个月或10次,以最先使用的为准,并限制在650.0℃以上使用一次。

3.1.10.2 The life of non-expendable base metal load sensors shall be limited by the maximum operating temperature and the number of calendar days since the first use.

非易耗型廉金属载荷传感器的寿命应受自首次使用以来的最高工作温度和日历天数的限制。

3.1.10.3 Records shall be maintained of the accumulated load sensor use above 500 ℉ or 260 ℃ including sensor batch number, load cycle, temperature, and use count. The use count shall include uses during SAT and TUS. When sensors are replaced after a single use, the sensor batch number shall be recorded and traceable to the load.

应保存载荷传感器在260℃以上的累计使用记录,包括传感器批号、载荷周期、温度和使用次数。使用次数应包括系统精度校验和温度均匀性测量期间的使用。当传感器单次使用后更换时,应记录传感器批号并可追溯到负载。

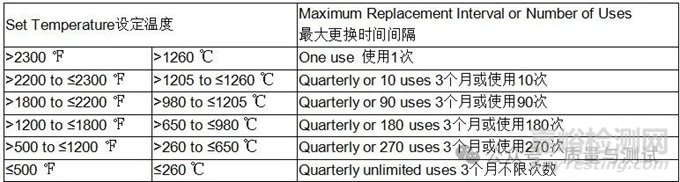

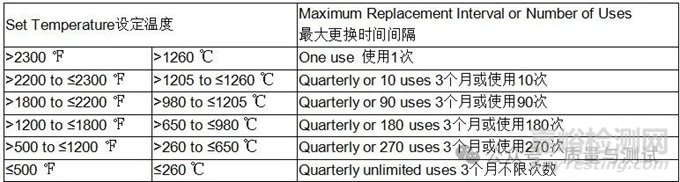

3.1.10.4 The maximum replacement interval or number of uses, whichever occurs first since first use of non-expendable base metal load sensors, shall comply with Table 6.

耐久型廉金属载荷传感器首次使用后的最大更换间隔或使用次数,以第1次使用为准,应符合表6。

Table 6 - Non-expendable base metal load sensor use temperature, interval or uses

耐久型廉金属载荷传感器的使用温度、间隔或用途

3.1.10.5 When load sensors are used in multiple qualified temperature ranges, the shortest interval or use shall apply.

当载荷传感器在多个合格的温度范围内使用时,应用最短的间隔。

Example 1: A sensor with nine uses at 2250.0 ℉ or 1232.0 ℃ has only one more use allowed in the 2200.0 to 2299.9 ℉ or 1204.5 to 1259.9 ℃ range, or any lower operating range. No uses remain at 2300.0 ℉ or 1260.0 ℃ or above.

例1:一个在1232.0℃使用有9次传感器,只允许在1204.5℃~1259.9℃范围内,或任何更低的工作范围内使用。在1260.0℃或更高的温度下不得使用。

Example 2: A sensor with 50 uses between 1400.0 ℉ and 1600.0 ℉ or 760.0 ℃ and 871.0 ℃ is then used at 1820.0 ℉ or 993.0 ℃.

例2:在760.0℃~871.0℃间使用50次传感器,然后在993.0℃使用。

The sensor has already exceeded the use limits for all ranges above 2199.9 ℉ or 1204.4 ℃.

The sensor is now subject to the 90 use limit as it has been used in a higher temperature range.

该传感器已经超过了2199.9℉或1204.4℃以上的所有范围的使用限制。该传感器现在受到90的使用限制,因为它已经在更高的温度范围内使用。

Example 3: A sensor with 50 uses between 1400.0 ℉ and 1600.0 ℉ or 760.0 ℃ and 871.0 ℃ is then used at 1015.0 ℉ or 546.0 ℃.

The sensor has already exceeded the use limits for all ranges above 2199.9 ℉ or 1204.4 ℃.

The sensor is subject to a 180 use limit as it has been used in the 1200.0 to 1799.9 ℉ or 648.9 to 982.2 ℃ temperature range.

例3:在1400.0℉和1600.0℉或760.0℃和871.0℃之间使用50个传感器,然后在1015.0℉或546.0℃使用。该传感器已经超过了2199.9℉或1204.4℃以上的所有范围的使用限制。该传感器受180的使用限制,因为它已经在1200.0至1799.9℉或648.9至982.2℃的温度范围内使用。

3.1.11 Sensor Calibration Results and Records传感器校准结果和记录

3.1.11.1 The results of sensor calibration or re-calibration shall be documented. The documentation shall include 传感器校准或重新校准的结果应记录下来。文件应包括:

a. Identification of the sensor, batch of sensors or wire/cable rolls.

传感器的识别,传感器的批次或电线/电缆卷。

b. Sensor type, e.g., K, N, E, RTD, etc.

传感器类型,如K, N, E, RTD等。

c. Date of calibration or recalibration.

校准或重新校准日期。

d. Quantity or length of wire/cable rolls represented in calibration report

在校准报告中显示电线/电缆卷的数量或长度。.

e. Identification if the calibration was initial or a recalibration.

识别是初始校准还是重新校准

f. The required calibration accuracy.

所需的校准精度。

g. Identification of the standard test sensor and standard test instrument used.

所使用的标准测试传感器和标准测试仪表的识别。

h. Nominal calibration temperatures.

名义校准温度。

i. Actual temperature readings of the sensor(s) being calibrated

正在校正的传感器的实际温度读数

j. Calibration technique referencing ASTM E220 or other internationally recognized standards.

参考ASTM E220或其他国际公认标准的校准技术

k. Correction factors or deviations/errors for each calibration temperature, including the average correction factor representing both ends for wire/cable rolls.

每个校准温度的修正系数或偏差/误差,包括代表电线/电缆卷两端的平均修正系数。

l. Documentation shall clearly state deviation (error) or correction factor.

文件应明确说明偏差(错误)或修正系数

m. A statement of traceability to NIST or other internationally recognized standards organization.

对NIST或其他国际公认标准组织的可追溯性声明

n. Identification of the calibration agency.

标定机构的识别。

o. Identification of technician performing calibration.

进行校准的技术人员的识别。

p. Approval of an authorized agent for the calibration agency.

对校准机构的授权代理人的批准。

q. User quality organization approval.

用户质量组织批准。

3.2 Instrumentation仪表化

3.2.1 General Instrumentation Requirements一般仪表要求

3.2.1.1 Conversion from millivolts to degrees or degrees to millivolts shall be in accordance with ASTM E230 or other internationally recognized standards.

从毫伏到度或度到毫伏的转换应符合ASTM E230或其他国际公认标准。

3.2.1.2 Output of sensors shall be converted to temperature readings by instruments specified herein or instruments of equal or greater accuracy.

应使用本标准规定的精度相同或更高精度的仪表,将温度传感器的输出转换为温度读数。

3.2.1.3 Instruments shall be calibrated in accordance with Table 7 and shall be traceable to NIST or other internationally recognized standards organization.

仪表应按照表7进行校准,并可溯源到NIST或其他国际公认的标准。

3.2.1.4 Process recording data collection shall be a minimum of six data points for each recorded sensor during each time at temperature processing cycle not to exceed 10-minute intervals.

过程记录的数据收集应为每个记录的传感器在每个温度处理周期不超过10分钟间隔的时间最少6个数据点。 在每次温度处理周期不超过10分钟的间隔,每个记录传感器应至少收集6个数据点。

3.2.1.4.1 For cycles where the time at temperature is <6 minutes, the data collection shall be ≤ once per minute.

对于温度持续时间<6分钟的周期,数据采集应≤每分钟一次。

3.2.1.5 Data collection intervals shall be sufficient to demonstrate conformance to sack time, heat-up, and cooling rate requirements数据收集间隔应符合保温时间、加热速率和冷却速率的要求。

3.2.1.5.1 The recording instrument shall actively record/collect data during the entire time that parts or raw material are in the thermal processing equipment. In cases where load sensors must be disconnected to transfer the load, users shall have other objective evidence of process compliance (e.g., data showing temperature drop from the temperature of other furnace recording sensor(s) compliant with the soak.

在工件或原材料进入热加工设备的整个过程中,记录仪表应主动记录/收集数据。在载荷传感器必须断开以转移载荷的情况下,用户应有其他符合工艺要求的客观证据(例如,数据显示温度降低与符合浸泡条件的其他炉子记录传感器)

Table 7 - Instruments and instrument calibration仪表及仪表校准

Notes:

(1) Instruments of equivalent or greater accuracy are acceptable可接受精度相当或更高的仪表。

(2) Applicable to quench or refrigeration equipment only仅适用于淬火或冷处理设备。

(3) Instrument calibration intervals shall be仪表校准间隔时间为:

(4) When the refrigeration and/or quench equipment sensor is connected to a channel in a furnace recording instrument the interval for calibration of that channel in the recording instrument shall be the same calibration interval as the other channels in the instrument.

当冷处理和/或淬火设备传感器连接到炉记录仪表的通道时,记录仪表中该通道的校准间隔应与仪表中其他通道的校准间隔相同。

(5)Field test instruments meeting the accuracy requirements of secondary standards may be used to calibrate SAT and TUS instruments in the field. These instruments shall be calibrated quarterly using a primary standard.

满足Ⅱ级标准精度要求的现场测试仪表可用于现场校准SAT和TUS仪表。这些仪表应每季度使用Ⅰ级标准进行校准。

(6) NIST or other internationally recognized standards organization. Per Manufacturer’s Specifications for Reference Standard Instruments (e.g., stability of 2 μV/V per year) and NIST or equivalent Calibration for Reference Standard Instruments.

NIST或其他国际公认的标准组织。根据参考标准仪表制造商的规范(例如,稳定性为每年2 μV/V)和NIST或等效的参考标准仪表校准。

(7) Includes wireless transmission systems包括无线传输系统。

(8) Instruments shall be stored and used in the environment specified by the instrument manufacturer.

仪表应在仪表制造商规定的环境中储存和使用。

(9) Calibration periods for instruments shall begin on the date of calibration.

仪表的校准周期从校准日期开始。

(10) Digital control instruments that only read in whole numbers shall have maximum calibration accuracy of ±2 ℉ or ±1 ℃ or ±0.2% of the temperature reading rounded inward towards the smaller whole number.

仅读取整数的数字控制仪表的最大校准精度应为±2℉或±1℃或温度读数的±0.2%向内修约到较小的整数。

(11)For thermal processing equipment that has documented “out of use/service” periods beyond the due date and extension days in Table 22, calibration of process instrumentation shall be performed before being returned to service.

对于热加工设备,其“停止使用/服务”期限超过了表22中规定的截止日期和延期日期,应在重新投入使用前对过程仪表进行校准。

3.2.2 Test Instruments (Primary Standard, Secondary Standard, and Field Test)

测试仪表(Ⅰ级标准,Ⅱ级标准和现场测试)

3.2.2.1 Primary and secondary standard instruments shall be digital and meet the calibration accuracy requirements of Table 7 in degrees of temperature or in millivolts that can be converted to demonstrate equivalent accuracy.

Ⅰ级和Ⅱ级标准仪表应是数字化的,并满足表7的校准精度要求,其温度或毫伏可以转换为显示等效精度。

3.2.2.2 Field test instruments shall be digital and have a minimum readability of 0.1 ℉ or 0.1 ℃ for any input and output used.

现场测试仪表应是数字化的,任何输入和输出的最小可读性为0.1℉或0.1℃。

3.2.2.3 Test instrument calibration shall be performed at a minimum of six simulated sensor input and/or output signals. These shall include the minimum and maximum of the operating range used for test or calibration and a minimum of four points in between either representing areas of normal operation or spaced at approximately equal intervals across the range in which the instrument is used for test or calibration.

测试仪表应在至少6个模拟传感器输入和/或输出信号下进行校准。其中应包括用于测试或校准的工作范围的最小值和最大值,以及其中表示正常工作区域或在仪表用于测试或校准的范围内以近似相等的间隔间隔的至少4个点。

3.2.2.3.1 For test instruments used only at a single temperature, the calibration shall be performed at that single temperature.

对于仅在单一温度下使用的测试仪表,校准应在该单一温度下进行。

3.2.2.4 Calibration shall be performed for each type of input and output used, e.g., each sensor type in use and for mV, mA, etc., if the instrument is used for these scales.

应对所用的每类输入和输出进行校准,例如,所用的每一种传感器,如果仪表用于这些刻度,则应校准毫伏、毫安等。

3.2.2.5 Calibration shall be performed on each channel in use that can be altered or adjusted individually, or on each group of channels that can be altered or adjusted as a group. Channels not in use shall be blocked or tagged to prevent unintentional use.

应对使用中的每个单独修改或调整的通道进行校准,或对每组可作为一组更改或调整的通道进行校准。不使用的通道应被封锁或贴上标签,以防止无意使用。

3.2.2.6 A test instrument meeting the accuracy of a secondary standard may be used in a production environment as a field test instrument. The calibration frequency shall be the same as a field test instrument and the instrument shall be operated within the environmental conditions specified by the instrument manufacturer.

满足Ⅱ级标准精度的测试仪表可以作为现场测试仪表在生产环境中使用。校准频率应与现场测试仪表相同,仪表应在仪表制造商规定的环境条件下操作。

3.2.3 Control, Recording, and Over-Temperature Instruments控制,记录和超温仪表

3.2.3.1 All control, recording, and over-temperature instruments shall be digital.

所有控制、记录和超温仪表都应是数字式的。

3.2.3.2 Digital recording instruments shall produce permanent records with a minimum readability of 0.1 ℉ or 0.1 ℃.

数字记录仪表应具有最低0.1℉或0.1℃的分辨率。

3.2.3.2.1 Digital recording instruments that only read in whole numbers may be used for 1 year after the release of AMS2750 Rev G and shall have maximum calibration accuracy of ±2 ℉ or ±1 ℃ or ±0.2% of the temperature reading rounded inward towards the smaller whole number.

仅读取整数的数字记录仪表可在AMS2750 Rev G发布1年后使用,校准精度最低为±2℉或±1℃或温度读数的±0.2%修约至较小的整数。

3.2.3.3 Instruments shall receive an unmodified signal from sensors except for analog to digital and digital to analog conversions, or a digitally processed, error-checked equivalent representation of a direct measured value.

除模拟量到数字量和数字量到模拟量的转换,或直接测量数值的数位处理、误差检查的等效表示以外, 仪表应从温度传感器接收未修正的信号。

3.2.3.4 Calibration shall be performed in the as-found condition taking into account any applied and documented offsets at a minimum of three simulated sensor inputs at the minimum, maximum and at least one point in the middle third of the entire qualified operating temperature range to document the as-found condition.

应在发现的条件下进行校准,考虑到至少三个模拟传感器输入的最小、最大和至少中间三分之一点的任何应用和记录的偏移,以记录发现的条件。

Example 1: A Class 2 ±10 ℉ furnace with a qualified operating temperature range of 300 to 1200 ℉ requires calibration at the Minimum = 300 ℉, at the Maximum = 1200 ℉, and at least 1 point in the middle third = 600 to 900 ℉.

例1:一个2±10°F的炉子,合格的工作温度范围为300°F至1200°F,需要在最低= 300°F,最高= 1200°F,中间三分之一处至少有一个点= 600至900°F进行校准。

Example 2: A Class 2 ±6 ℃ furnace with a qualified operating temperature range of 200 to 1100 ℃ requires calibration at the Minimum = 200 ℃, at the Maximum = 1100 ℃, and at least 1 point in the middle third = 500 to 800 ℃.

例2:一个2±6℃的炉,合格的工作温度范围为200℃至1100℃,需要在最低= 200℃,最高= 1100℃,中间三分之一处至少有一个点= 500℃至800℃进行校准。

3.2.3.5 For equipment that does not have a defined qualified operating temperature range (e.g., quench tanks and refrigeration equipment), calibration shall be performed at a minimum of three simulated sensor inputs at the minimum, maximum and at least one point in the middle third of the operating range used. Users shall have the ability to identify the operating range used for each piece of quench and/or refrigeration equipment.

对于没有确定的合格工作温度范围的设备(例如,急冷罐和制冷设备),应在使用的工作范围的最小、最大和中间三分之一的至少三个模拟传感器输入进行校准。用户应能够识别每件淬火和/或制冷设备的操作范围。

3.2.3.5.1 Instrument calibration points for equipment with a qualified operating temperature range and an unqualified operating range of use, such as a cryogenic-temper unit, shall be in accordance with 3.2.3.4 for the qualified operating range and in accordance with 3.2.3.5 for the unqualified range of use.

对工作温度范围合格、不合格使用温度范围的设备,如低温回火装置,其工作温度范围合格的按3.2.3.4,使用温度范围不合格的按3.2.3.5。

3.2.3.6 For control, recording, and over-temperature instruments used only at a single temperature, the instrument calibration shall either be performed at that single temperature of use, or in accordance with 3.2.3.4 or 3.2.3.5 as applicable.

对于仅在单一温度下使用的控制、记录和超温仪表,仪表校准应在该单一使用温度下进行,或按照适用的3.2.3.4或3.2.3.5进行。

3.2.3.7 The instrument error is the difference between the readings of the instrument being calibrated and the field test instrument. When any documented modification offsets are used in production, the reading of the instrument being calibrated shall be corrected algebraically.

仪表误差是指被校准仪表读数与现场测试仪表读数之间的差值。当任何记录在案的修正偏移量用于生产时,被校准仪表的读数应进行代数校正。

3.2.3.8 Following any calibration adjustments, the instrument shall be verified in accordance with 3.2.3.4, 3.2.3.5, or 3.2.3.6 as applicable to document the as-left condition.

在任何校准调整后,仪表应按照3.2.3.4、3.2.3.5或3.2.3.6(适用于记录保留状态)进行验证

3.2.3.9 Calibration shall be performed on each channel in use that can be altered or adjusted individually, or on each group of channels that can be altered or adjusted as a group.

应对使用中的每个可单独更改或调整的通道进行校准,或对每组可作为一组更改或调整的通道进行校准。

3.2.3.10 All active channels of multi-channel digital recording instruments shall be calibrated. Channels not in use shall be identified to prevent unintentional use.

多通道数字记录仪表的所有有源通道都应进行校准。未使用的通道应加以识别,以防止意外使用。

3.2.3.11 When the control and recording system is integrated such that the digitally displayed control value and the digitally recorded value are generated from the same measurement circuit and cannot be different, it is only necessary to document a single displayed/recorded value for the control reading.

当控制和记录系统集成在一起,使数字显示的控制值和数字记录的值从相同的测量电路产生且不能不同时,只需要记录一个显示/记录的值作为控制读数。

3.2.3.12 For retort furnaces, the temperature of the furnace shall be controlled such that the specified temperature is maintained within the retort. As a minimum, the control instrument shall be calibrated across the temperature range of use within the retort.

对于蒸馏炉,应控制其温度,使蒸馏炉内的温度保持在规定的温度范围内。作为最低限度,控制仪表应在蒸馏器内使用的温度范围内进行校准。

3.2.3.13 Refrigeration and quench equipment control instruments that display temperature shall be calibrated. All recording instruments shall be calibrated (see Table 7).

显示温度的制冷和淬火设备控制仪表应进行校准。所有记录仪表都应进行校准(见表7)。

3.2.3.14 The timing function for all digital recording instruments and data acquisition systems shall be calibrated at least annually and shall be accurate to ±1 min/h. The calibration may be performed for a time ≤1 hour and the results converted to meet ±1 min/h.

所有数字记录仪表和数据采集系统的定时功能应至少每年校准一次,并应精确到±1分钟/小时。校准时间≤1小时,结果转换为±1分钟/小时。

3.2.3.15 External timing devices such as timers, clocks, stopwatches, etc., shall be calibrated at least every 2 years and shall be accurate to ±1 s/min.

外部定时装置,如计时器、时钟、秒表等,应至少每两年校准一次,并应精确到±1秒/分钟。

3.2.3.16 As an alternative to 3.2.3.14 or 3.2.3.15, a defined digital synchronization of digital recording instruments and data acquisition systems or external timing devices to NIST or other international equivalent via satellite, internet, or telephonic systems at least monthly to support a ±1 min/h accuracy for digital recording instruments and/or ±1 sec/min for external timing devices is acceptable.

作为3.2.3.14或3.2.3.15的替代方案,数字记录仪表和数据采集系统或外部定时设备通过卫星、互联网或电话系统与NIST或其他国际等效设备进行定义的数字同步,至少每月一次,以支持±1分钟/小时的精度的数字记录仪或±1秒/分钟外部计时装置是可以接受的。

3.2.3.17 Wireless equipment which performs the analog to digital conversion at the furnace and transmits a digital signal to the recording instrument is permitted. However, calibration of the complete wireless system (wireless transmitter, wireless receiver and associated control and recording instruments) is required.

允许在电炉处执行模拟到数字转换并将数字信号传输到记录仪表的无线设备。但是,需要对整个无线系统(无线发射器、无线接收器和相关的控制和记录仪表)进行校准。

3.2.3.18 Correction Factors for Instruments仪器校正系数

3.2.3.18.1 Extrapolation of calibration correction factors above the highest calibration temperature and below the lowest calibration temperature is prohibited by any calibration source except NIST or other internationally recognized standards organization.

除NIST或其他国际公认的标准组织外,任何校准源都禁止在最高校准温度以上和最低校准温度以下外推校准校正因子。

3.2.3.18.2 Interpolation of correction factors between two known calibration points is permitted using the linear method. Alternatively, the correction factor of the nearest calibration point shall be used. Whichever method is used shall be defined and applied consistently.

允许使用线性方法在两个已知的校准点之间插值校正因子。或者,应使用最近的校准点的校正系数。无论采用哪一种方法,都应得到一致的定义和应用。

3.2.4 Electronic Records电子记录

3.2.4.1 An electronic record is any combination of text, graphics, data, audio, pictorial, or other information represented in digital form that is created, modified, maintained, archived, retrieved, or distributed by a computer system.

电子记录是指由计算机系统创建、修改、维护、存档、检索或分发的以数字形式表示的文本、图形、数据、音频、图像或其他信息的任何组合。

3.2.4.2 When using a system (control, recording or data acquisition) that creates electronic records the system shall:

当使用创建电子记录的系统(控制、记录或数据采集)时,该系统应:

a. Create records that cannot be altered without detection.

创建无法在不被检测的情况下更改的记录。

b. Provide software and playback utilities as a means of examining and/or compiling the data but shall not allow the user any means for altering the source data.

提供软件和回放工具作为检查和/或汇编数据的手段,但不允许用户使用任何方法更改源数据

c. Provide the ability to generate accurate and complete copies of records in both human readable and electronic form suitable for inspection, review, and duplication.

提供生成准确而完整的记录副本的能力,该副本可以是人类可读的,也可以是适合检查、审查和复制的电子形式。

d. Be capable of providing evidence the record was reviewed by recording an electronic review, or a method of printing the record for a physical marking verifying review.

能够通过记录电子评审或打印记录以进行物理标记验证评审的方法,提供对记录进行评审的证据。

e. Support protection, retention, and retrieval of accurate records throughout the record retention period.

在记录保存期间,支持对准确记录的保护、保留和检索。

f. Ensure that the hardware and/or software shall operate throughout the retention period as specified in 3.7.

确保硬件和/或软件在3.7规定的保留期内正常运行。

g. Provide methods of protection, such as a password, to limit system access to only individuals whose authorization is documented.

提供保护方法,例如密码,以限制系统的访问权限,只有获得文件授权的个人才能访问

3.2.4.3 Evidence shall be provided that software revisions are verified to ensure continued compliance with the material or process specification requirements and once installed have not altered programs, recipes, or other means used to control thermal processing parameters.

应提供证据证明软件修订版经过验证,以确保持续符合材料或工艺规范的要求,并且一旦安装,软件修订版没有改变用于控制热加工参数的程序、配方或其他手段。

3.2.5 Instrumentation Calibration Results and Records仪表仪表校准结果和记录

3.2.5.1 The most recent successful calibration status shall be readily accessible at or in close proximity to the thermal processing equipment. As a minimum, the information shall include:

最近一次成功的校准状态应在热加工设备附近或附近易于获取。至少,信息应包括:

a. Instrument number or furnace number.

仪表编号或炉号。

b. Date the calibration was performed.

标定完成日期。

c. Due date of the next calibration.

下一次校准的截止日期

d. Identification of the technician who performed the calibration.

进行校准的技术人员的识别

e. Indication if any limitations or restrictions of the calibration. A notation such as “see report” is acceptable指示是否有任何限制或校准的限制。像“见报告”这样的符号是可以接受的。

3.2.5.2 The results of instrument calibration shall be documented. As a minimum, the documentation shall include仪表校准结果应形成文件。文件至少应包括:

a. Unique identification of the instrument仪表的唯一标识。

b. Make and model of the instrument calibrated校准仪表的品牌和型号。

c. Unique Identification of the test instrument used during calibration在校准过程中使用的测试仪表的唯一标识。

d. Identification of each sensor type in use (e.g., Type K, N, etc.) and form (e.g., V, mA, etc.) if the instrument is used for these scales如果该仪表用于这些量表,则要识别所使用的每个传感器类型(如K型、N型等)和形式(如V、mA等)。

e. Identification of location where signal was input (only required for measurement systems employing the alternate SAT)信号输入位置的识别(仅用于使用备用SAT的测量系统)。

f. Required calibration accuracy需要的校准精度。

g. As-found data at each calibration point and as-left data if any adjustments are made, to include每一个校准点的发现数据和剩余数据(如进行任何调整),包括:

1. Nominal test temperature名义测试温度。

2. Reading of the instrument being calibrated被校准仪表的读数

3. Error or correction factor of test instrument (optional or when specified by the customer)测试仪表的误差或校正系数(可选或由客户指定)。

4. Error or correction factor of instrument under test (corrected or uncorrected for test instrument error when specified)被测仪表的误差或校正系数(按规定对测试仪表的误差进行校正或未校正)。

h. Correction and modification offsets as-found and as-left in accordance with 3.2.6.

根据3.2.6对发现和剩余的偏移量进行修正和修改。

i Instrument calibration pass or fail statement仪表校准通过或失败的声明。

j. Any limitations or restrictions of the calibration任何限制或校准的限制。

k. Date the calibration was performed标定完成日期。

l. Due date of the next calibration下一次校准的截止日期。

m. Statement of traceability to NIST or other internationally recognized standards organization.

对NIST或其他国际公认标准组织的可追溯性声明。

n. Identification of the technician who performed the calibration进行校准的技术人员的识别。

o. Identification of the calibration agency if calibration is not performed internally如果内部没有进行校准,则标识校准机构。

p. Approval of an authorized agent for the calibration agency if not performed internally对校准机构的授权代理的批准(如果不是内部执行)。

q. User quality organization approval用户质量组织批准。

注:AMS 2750D后有要求

3.2.6 Thermal Process Equipment Instrument Correction and Modification Offsets (see 2.2.38.1 and 2.2.38.2)

热加工设备仪表校正和修正偏移(见2.2.38.1和2.2.38.2)

3.2.6.1 General Instrument Correction and Modification Offset Requirements一般仪表校正和修正偏移量要求

3.2.6.1.1 If instrument correction and/or modification offsets are used, a documented procedure shall exist describing when and how to make instrument correction and/or modification offsets.

如果使用了仪表校正和/或修正偏移量,应制定文件程序,说明何时以及如何进行仪表校正和/或修正偏移量。

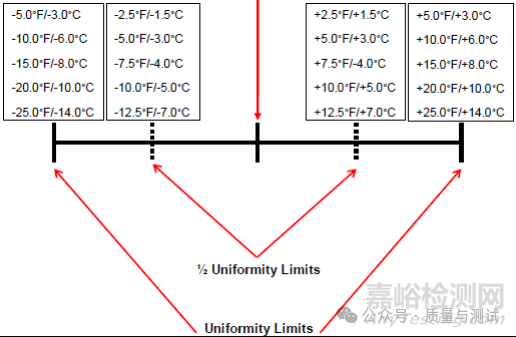

3.2.6.1.2 The maximum cumulative correction offset shall not exceed the uniformity tolerance for the thermal processing equipment or ±10.0 ℉ or ± 6.0 ℃ for refrigeration and quench instruments. (e.g., a Class 2 furnace instrument is limited to a maximum correction offset of ±10.0 ℉ or ±6.0 ℃).

最大累积校正偏移量不得超过热加工设备的均匀度公差或制冷和淬火仪表的±10.0℉或±6.0℃。(例如,2类炉仪表的最大校正偏移量限制在±10.0℉或±6.0℃)。

3.2.6.1.3 Instrument correction and/or modification offsets may be either internal (electronic) or external (manual), and shall be included in the calibration, SAT, and TUS documentation.

仪表校正和/或修正偏 移量可以是内部(电子)或外部(手动),并应包括在校准、SAT和TUS文件中。

3.2.6.1.4 Controlling instrument modification offsets for TUS shall not exceed the allowances in Table 15 or 16为TUS控制的仪表修正补偿不得超过表15或表16中的余量。

3.2.6.1.5 TUS modification offsets are not permitted on recorder channels other than for the channel recording the control sensor temperature.

除了记录控制传感器温度的通道外,在记录通道上不允许TUS修改偏移。

3.2.6.1.6 SAT modification offsets are not allowed. Control and recording instrument correction offsets for SAT shall not exceed the allowance in Table 15 or 16.

SAT修改偏移是不允许的。SAT的控制和记录仪表校正误差不应超过表15或表16中的允许值。

3.2.6.1.7 For load sensor systems used in production, correction offsets are allowed, but not modification offsets.

对于生产中使用的负载传感器系统,允许校正偏移,但不允许修改偏移。

3.2.6.1.8 When correction and/or modification offsets are implemented or changed, the effect of the new offset value over the entire qualified operating temperature range shall be evaluated. Objective evidence that the new offset value would not cause a failure of any other calibration, SAT, or TUS shall be documented.

当实施或改变校正和/或修改偏移量时,应评价新的偏移值在整个合格工作温度范围内的影响。新的偏移值不会导致任何其他校准、SAT或TUS失败的客观证据应记录在案。

3.3 Thermal Processing Equipment热处理设备

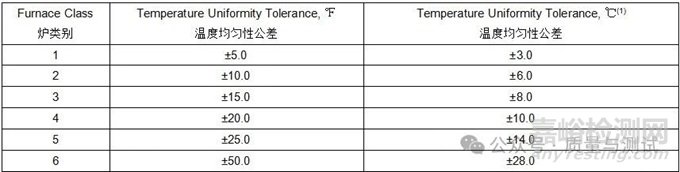

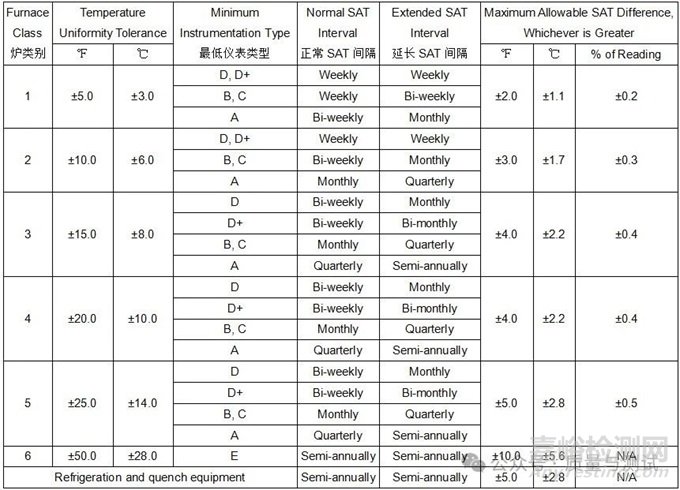

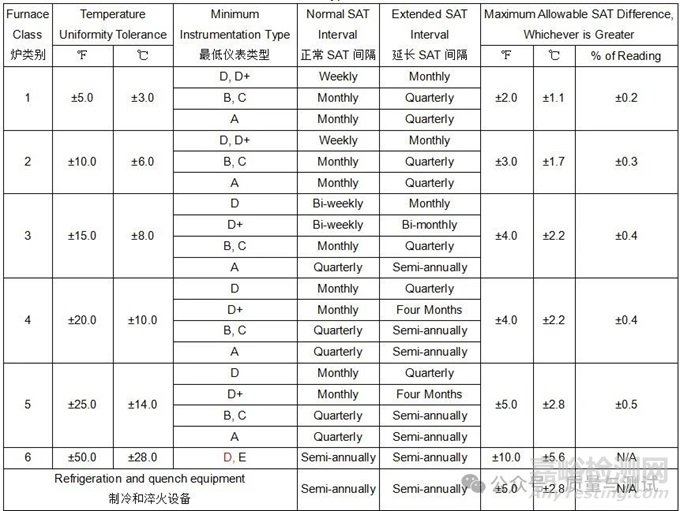

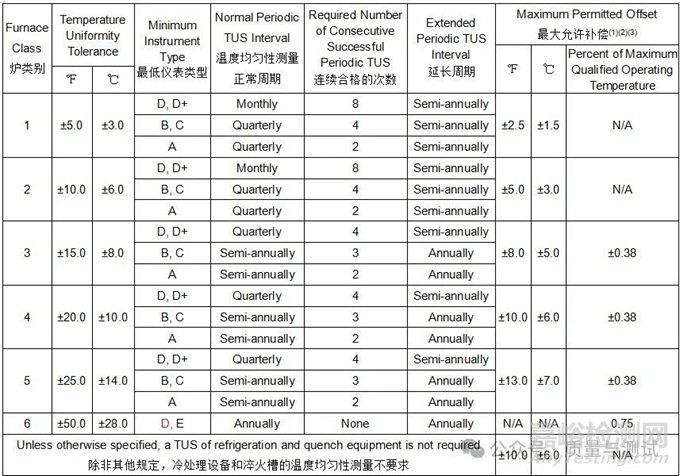

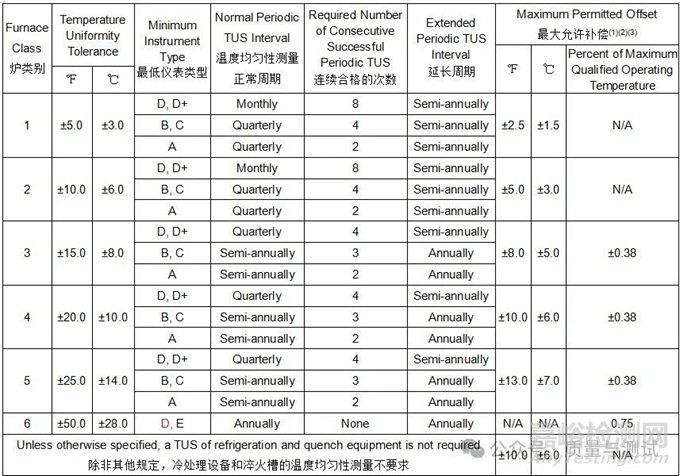

3.3.1 Furnace classes are defined in Table 8 and are based on the furnace class specified. When not specified, the furnace class shall meet the TUS requirements established in the governing specification for the parts or raw material being processed. Instrumentation types are defined by the level of instrumentation used to control, record, or indicate the desired temperature. Intervals for controlling and recording instrument calibration, SATs, TUSs, are based on the combined furnace class and instrumentation type stated in Table 7, 11, 12, 15, or 16.

表8中定义了加热炉的类别,并以指定的加热炉类别为基础。如果没有规定,炉级应满足TUS对正在加工的部件或原材料的控制规范中建立的要求。仪表类型由用于控制、记录或指示所需温度的仪表级别来定义。控制和记录仪表校准的时间间隔,SAT, TUSs,是基于综合熔炉等级和仪表类型,表7,11,12,15,或16所述。

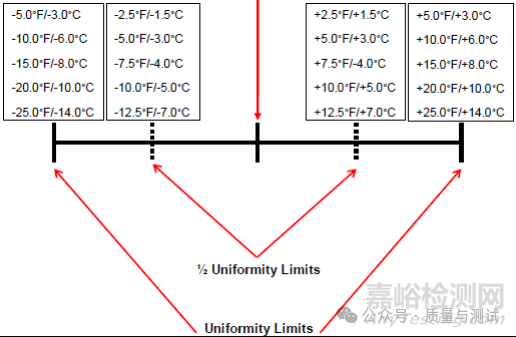

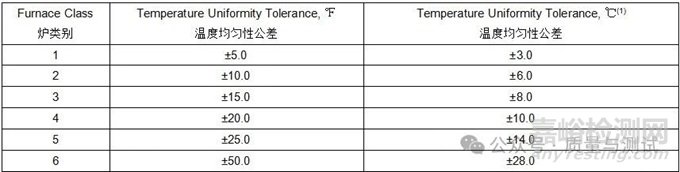

Table 8 - Furnace class uniformity tolerances炉类均匀性公差

Notes:

(1) Some design authorities require TUS tolerances of ±5.0 ℃ and ±7.0 ℃ for Class 2 and Class 3, thermal processing equipment 一些设计机构要求2类和3类热处理设备的TUS公差为±5.0℃和±7.0℃。

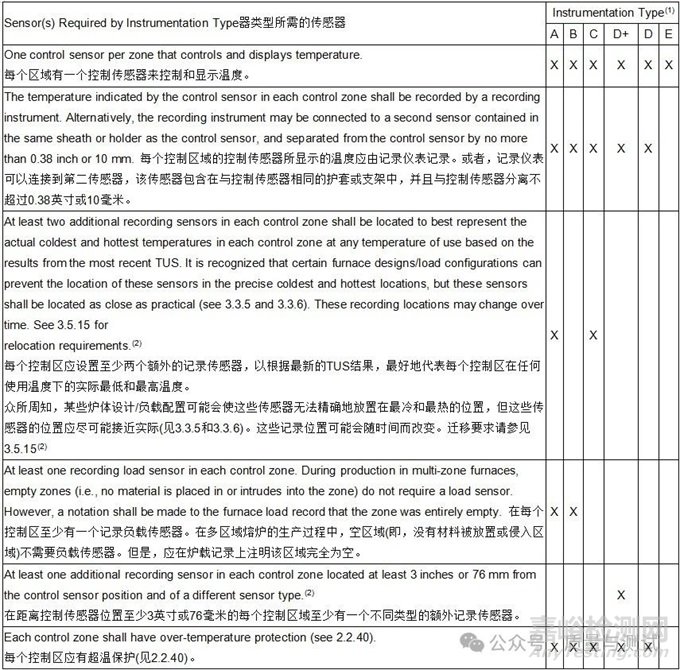

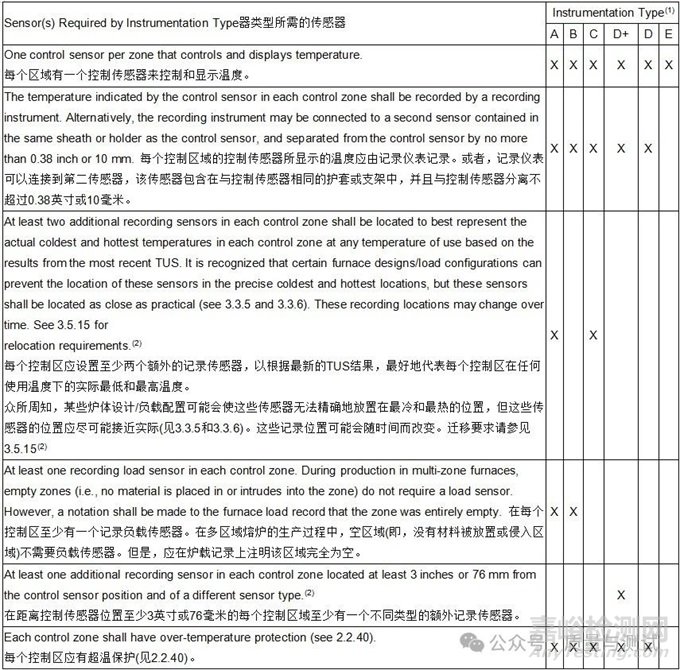

3.3.2 Requirements for furnace instrumentation type classification are shown in Table 9.

炉子仪表类型分类要求如表9所示。

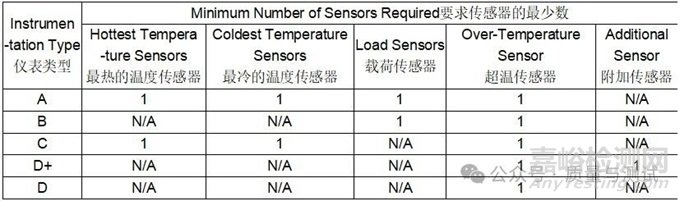

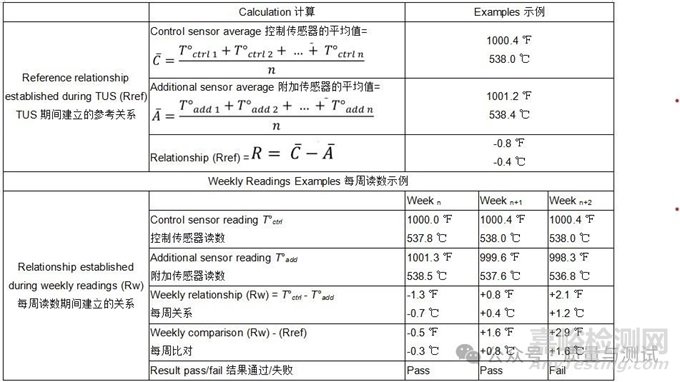

Table 9 - Instrumentation type requirements仪表类型需求

Notes:

(1) Instrumentation types are listed in descending order of quality from left to right; i.e., A is better than B, etc.

从左到右按照质量降序列出了工具类型;例如,A比B好,等等。

(2) The over-temperature protection sensor may also be utilized as the recording sensor representing the hottest location for instrumentation Type A or C or as the additional recording sensor for Type D+ if in the proper location.

过温保护传感器也可用作记录传感器,表示A或C类仪表的最热位置,如果位于适当位置,也可用作D+类仪表的附加记录传感器

3.3.3 Instrumentation Requirements for Refrigeration Equipment and Quench Systems

冷处理设备和淬火系统的仪表要求

3.3.3.1 All refrigeration equipment shall have a temperature controller. This temperature controller requirement is not applicable to liquid nitrogen, dry ice, or dry ice/liquid-cooled containers.

所有的冷处理设备都应该有一个温度控制器。此温度控制器要求不适用于液氮、干冰或干冰/液冷容器。

3.3.3.2 All refrigeration equipment shall be equipped with a temperature recording instrument where time-at-temperature (minimum, maximum, or both) is required.

所有的冷处理设备都应配备温度记录仪表,时间-温度(最低,最高,或两者)要求。

3.3.3.3 Unless otherwise specified, the requirements of 3.3.3.1 and 3.3.3.2 are not applicable during transportation of materials at sub-ambient temperatures

除另有规定外,在亚环境温度下的物料运输中,不适用3.3.3.1和3.3.3.2的要求。.

3.3.3.4 Quench systems (immersion or spray) shall be equipped with a sensor that is recorded by recording instrument where temperature (minimum, maximum, or both) is required.

淬火系统(浸入式或喷雾式)应配备传感器,当要求温度(最低、最高或两者同时)时,该传感器的温度可由记录仪表记录。

3.3.4 Additional Sensors附加传感器

There is no limit to the number of additional recording or load sensors in any control zone, but their use shall be defined in controlled operating instructions, or procedures.

在任何控制区附加记录或载荷传感器的数量没有限制,但它们的使用应在受控操作说明书或程序中定义。

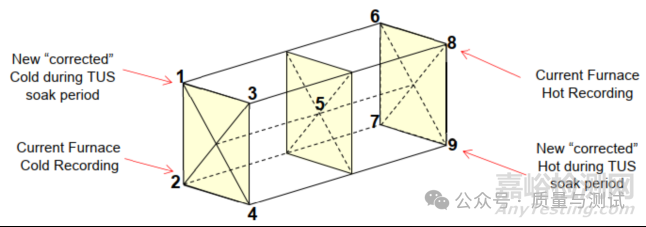

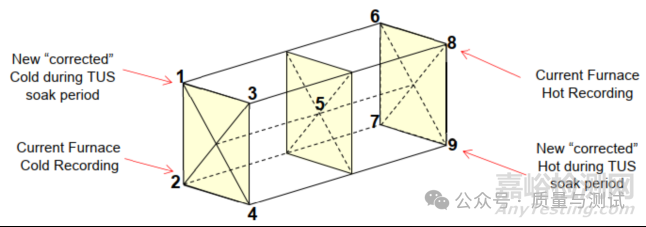

3.3.5 Hot and cold temperature sensors, when required for instrument Types A and C, as stated in Table 10, may be inserted in heat sinks (see 2.2.27), and positioned at the hottest and coldest temperature locations of the control zone based on the most recent TUS when heat sinks of similar configuration are used during the TUS.

如表10所示,当A、C类仪表需要时,可将热、冷温度传感器插入散热器(见2.2.27),并在TUS期间使用类似配置的散热器时,根据最近的TUS将其放置在控制区最热和最冷的温度位置。