您当前的位置:检测资讯 > 生产品管

嘉峪检测网 2024-08-06 20:32

无菌屏障系统的保护功能,是基于其完整性良好,所以完整性就成为无菌屏障系统性能指标的一项重要要求。

先看看法规对这块的要求

EU GMP Annex 1

8.48 Where materials, equipment, components and ancillary items are sterilised in sealed packaging or containers, the packaging should be qualified for minimizing the risk of particulate, microbial, endotoxin/pyrogen or chemical contamination, and for compatibility with the selected sterilisation method. The packaging sealing process should be validated. The validation should consider the integrity of the sterile protective barrier system, the maximum hold time before sterilisation and the maximum shelf life assigned to the sterilised items. The integrity of the sterile protective barrier system for each of the sterilised items should be checked prior to use.

如果物料、 设备、 组分和辅助用品在密封包装或容器中灭菌,包装应经过确认,以最大限度减少微粒、 微生物、 内毒素/热原或化学污染的风险, 并与所选灭菌方法兼容。 包装密封工艺应经过验证。 验证应考虑无菌保护屏障系统的完整性、 灭菌前的最长保持时间以及被灭菌物品的最长有效期。 应在使用前检查每种被灭菌物品的无菌保护屏障系统的完整性。

作为完整性的一部分,封口机的封口效果应该如何考察?

热封效果通常主要通过目测检查,一般要求密封完成后,热合线平整、无褶皱、无灼化或压穿、无开封、无穿孔或撕开、无材料分层或分离。

但这样足够了么?可能不够,因为有些泄露,是肉眼无法识别的,可能得用一些特殊的测试方法。今天主要就是聊聊这个

以下内容分享自

ASTM: American Society for Testing and Materials 美国材料与试验协会

ASTM F1929-23(国内的YY/T0681.4-2021参考的这个的之前版本)

Standard Test Method for Detecting Seal Leaks in Porous Medical Packaging by Dye Penetration

通过染料渗透检测多孔医药包装密封泄漏的标准试验方法。

1、 Scope范围

1.1 This test method defines materials and procedures that will detect and locate a leak equal to or greater than a channel formed by a 50 μm (0.002 in.) wire in package edge seals formed between a transparent material and a porous sheet material. A dye penetrant solution is applied locally to the seal edge to be tested for leaks. After contact with the dye penetrant for a specific time, the package is visually inspected for dye penetration.

此测试方法定义了材料和程序,它们能够检测并定位在透明材料和多孔片材料之间的包装边缘密封处形成的等于或大于由50微米(0.002英寸)线形成的通道的泄漏。将染料渗透溶液局部应用于要测试的密封边缘。在与染料渗透剂接触特定时间后,对包装进行目视检查以查找染料渗透。

1.2Three dye application methods are covered in this test method: injection, edge dip, and eyedropper.

此测试方法包括三种染料施加方法:注射、边缘浸染和滴注

1.3These test methods are intended for use on packages with edge seals formed between a transparent material and a porous sheet material. The test methods are limited to porous materials which can retain the dye penetrant solution and prevent it from discoloring the seal area for a minimum of 5 seconds. Uncoated papers are especially susceptible to leakage and must be evaluated carefully for use with each test method.

这些测试方法旨在用于具有透明材料和多孔片材料之间形成的边缘密封的包装上。测试方法限于能够保留染料渗透溶液并防止其在至少5秒内使密封区域变色的多孔材料。未涂层的纸张特别容易泄漏,必须仔细评估每种测试方法的使用

1.4These test methods require that the dye penetrant solution have good contrast to the opaque packaging material.

这些测试方法要求染料渗透溶液与不透明的包装材料形成良好的对比度。

1.5The values are stated in International System of Units (SI units) and English units. Either is to be regarded as standard.

值以国际单位制(SI单位)和英制单位表示。两者都被视为标准。

1.6This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

本标准不声称解决与其使用相关的所有安全问题(如果有的话)。标准的使用者有责任在使用前建立适当的安全、健康和环保实践,并确定法规限制的适用性。

1.7This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

这项国际标准是根据世界贸易组织技术性贸易壁垒(TBT)委员会发布的《国际标准、指南和建议的发展原则》中确立的国际公认的标准化原则制定的。

2. Referenced Documents引用的文件

2.1 ASTM Standards: F17 Terminology Relating to Primary Barrier Packaging

2.2 ANSI Standards: Z1.4 Sampling Procedures and Tables for Inspection by Attributes

3. Terminology术语

3.1 wicking - the migration of a liquid into the body of a fibrous material. This is distinct from a leak as defined in Terminology F17.

毛细作用,液体向纤维材料内移动,和F17的术语不是一个概念

3.2 dye penetrant - an aqueous solution of a dye and a surfactant designed to penetrate and indicate a defect location in the time prior to the onset of wicking which could mask its presence.

一种染色剂和一种表面活性剂的混合水溶液,设计成在发生毛细作用(会掩盖缺陷的存在)前的时段内用以指示缺陷的部位

3.3 channel - any unimpaired pathway across the entire width of the intended seal.

穿过预期密封区域整个宽度的任何未受损的路径

4. Significance and Use意义和用途

4.1 Harmful biological or particulate contaminants may enter the medical package through leaks, which are frequently found at seals between package components of the same or dissimilar materials. Leaks may also result from a pinhole in the packaging material.

有害的生物或颗粒污染物可能通过泄漏进入医疗包装中,这些泄漏通常发生在相同或不同材料的包装组件之间的密封处。泄漏也可能是由包装材料中的针孔造成的。

4.2 It is the objective of this test method to visually observe the presence of channel defects by the leakage of dye through them.

这个测试方法的目标是通过染料的泄漏来直观地观察通道缺陷的存在。

4.3 This dye penetrant procedure is applicable only to individual leaks in a package seal. The presence of a number of small leaks, as found in porous packaging material, which could be detected by other techniques, will not be indicated.

这种染料渗透程序仅适用于包装密封中的单个泄漏。在多孔包装材料中发现的许多能通过其他技术被检测到的小泄漏将不会被指出。

4.4 There is no general agreement concerning the level of leakage that is likely to be deleterious to a particular package. However, since these tests are designed to detect leaks, components that exhibit any indication of leakage are normally rejected.

关于哪种程度的泄漏可能对特定包装有害,目前没有普遍的共识。然而,由于这些测试旨在检测泄漏,通常那些显示出任何泄漏迹象的组件都会被拒绝

4.5 These procedures are suitable to verify and locate leakage sites. They are not quantitative. No indication of leak size can be inferred from these tests. The methods are usually employed as a pass/fail test.

这些程序适合于验证和定位泄漏点。它们不是定量的。从这些测试中无法推断出泄漏的大小。这些方法通常用作合格/不合格测试。

4.6 The dye solution will wick through any porous material over time, but usually not within the maximum time suggested. If wicking does occur, it may be verified by observing the porous side of the subject seal area. The dye will have discolored the surface of the material. Refer to Appendix X1 for details on wicking and guidance on the observance of false positives.

染料溶液会随着时间的推移通过任何多孔材料,但通常不会在建议的最大时间内发生。如果确实发生了毛细现象,可以通过观察密封区域的多孔侧面来验证。染料会使材料表面变色。有关毛细现象的详细信息和观察假阳性的指导,请参考附录X1

5. Apparatus仪器、设备

5.1 Means of breaching one of the packaging materials such as a small knife. (Method A)

破坏包装材料的方法,如使用小刀。(方法A)

5.2 Dye Dispenser, such as an eyedropper or syringe for injection of the dye penetrant solution. (Method A)

染料分配器,如用于注射染料渗透溶液的滴管或注射器。

5.3 Dye Solution Container (Method B)

染料溶液容器(方法B)

5.4 Scissors or other cutting instrument. (Method B)

剪刀或其他切割工具。(方法B)

5.5 Eyedropper or 1 Mil. Pipelle. (Method C)

滴管或1毫升的移液管。(方法C)

5.6 Microscope or optical loop with magnification of 5x to 20x (optional for all methods).

放大5倍至20倍的显微镜或光学放大镜(所有方法的可选设备)

5.7 Aqueous dye penetrant solution consisting of a carrier, a surfactant, and an indicator dye. The surfactant should be nonionic. The chemical properties of the surfactant should be as follows: surface tension between 30 mN/m to 33 mN/m, hydrophilic/lipophilic balance (HLB) greater than 10, and critical micelle concentration (CMC) less than 2000 ppm. The formula of the solution by weight:

水性染料渗透溶液由载体、表面活性剂和指示染料组成。表面活性剂应该是非离子型的。表面活性剂的化学性质应如下:表面张力在30 mN/m至33 mN/m之间,亲水/亲油平衡(HLB)值大于10,临界胶束浓度(CMC)小于2000 ppm。按重量计算的溶液配方为

Note 1: The solution must remain homogeneous. If precipitate is noted, the solution must be replaced.

注意1:溶液必须保持均匀。如果发现有沉淀,必须更换溶液。

5.7.1 If other colored or fluorescent dyes are substituted for toluidine blue, their precision and bias must be experimentally determined.

如果使用其他颜色或荧光染料替代甲苯胺蓝,必须通过实验确定它们的精确度和偏差。

5.7.2 Because of the viscosity of many surfactants, the preparation of the solution is most easily accomplished by first taring a container with about 10% of the required amount of water on a scale. The appropriate amount of surfactant is added to the water by weight and the mixture gently stirred. Vigorous stirring or shaking is not recommended, as it may cause foaming that may be difficult to dissipate. Once the surfactant is dissolved, the remaining water can then be added, followed by the toluidine blue dye.

由于许多表面活性剂的粘度,最简便的溶液制备方法是首先在秤上用容器称量所需水量的大约10%。然后按重量向水中加入适量的表面活性剂,并轻轻搅拌混合物。不建议剧烈搅拌或摇晃,因为这可能会产生难以消散的泡沫。一旦表面活性剂溶解,就可以加入剩余的水,然后加入甲苯胺蓝染料。

6. Safety Precautions安全防护措施

6.1 Injecting dye penetrant into a package with a hypodermic needle and syringe is a common method for performing this test. This practice can result in puncture of the skin with a contaminated needle and is therefore not recommended.Because of this hazard, it is recommended that the dye penetrant is dispensed using a flexible tube attached to a syringe through an opening formed with an appropriate cutting instrument.

使用注射针和注射器将染料渗透剂注入包装是执行此测试的常用方法。这种做法可能导致皮肤被污染的针头刺破,因此不推荐使用。由于这种危险,建议使用适当切割工具形成的开口,通过连接到注射器的柔性管来分配染料渗透剂。

7. Test Specimen试样

7.1 The test specimen shall consist of a complete packaged device, empty packages, or edge seal samples. Blemished, rejected, or dummy products may be used if they will not affect test results and are recorded prior to the test.

测试样品应包括完整的包装设备、空包装或边缘密封样品。如果它们不会影响测试结果,并且在测试前已记录,那么可以使用有瑕疵的、被拒绝的或假的产品

8. Calibration and Standardization校准和标准化

8.1 Since these procedures are not quantitative, no calibration is required.

由于这些程序不是定量的,因此不需要校准。

9. Sampling取样

9.1 The number of samples tested should be adequate to be predictive of performance. Caution should be taken when eliminating samples with defects as this can bias the results.

See ANSI ASOC Z1.4.

测试的样本数量应足够,能够预测性能。在淘汰有缺陷的样本时要小心,因为这可能会对结果产生偏差。

参见 ANSI ASOC Z1.4。

10. Conditioning调节

10.1 Packaging must be free of condensation or any other source of liquid water. Water already in the seal defects may render them undetectable with a dye penetrant. If there is any indication that the package has been exposed to any liquid, it must be thoroughly dried at its typical storage temperature before testing.

包装必须无凝结水或任何其他液态水的来源。已经存在于密封缺陷中的水可能使它们在使用染料渗透剂时无法被探测到。如果有任何迹象表明包装已暴露于任何液体,那么在测试前必须在其典型的储存温度下彻底干燥。

10.2 If conditioning is required, standard conditioning atmosphere of 23±2°C or 73.4±3.6°F and 50±2% relative humidity is recommended, for a minimum of 24 hr, prior to testing.

如果需要进行状态调节,建议在测试前至少24小时,将包装置于标准调节环境中,即温度保持在23±2°C或73.4±3.6°F,相对湿度保持在50±2%。

11. Procedure程序

11.1 Method A (Injection Method):方法A(注射法)

11.1.1 Inject sufficient dye penetrant into the package to cover the longest edge to a depth of approximately 5mm or 0.25 in. (see 6.1 for safety precautions).

向包装内注入足够的染料渗透剂,以覆盖最长边缘至大约5毫米或0.25英寸的深度(关于安全预防措施,见6.1)。

11.1.2 Visually examine the seal area through the transparent side of the package. Observe the package seal area for penetration of the dye solution across the seal width. Channels in the seal will be readily detected. Use 5 seconds per side mar as a guide for a 4 sided package. Total time should be less than or equal to 20 seconds. With prolonged exposure, wicking of dye through the porous packaging will color the entire seal area, making defect detection difficult. An optical device with 5x to 20x magnification may be used for detailed examination.

通过包装的透明侧面目视检查密封区域。观察包装密封区域染料溶液是否穿透密封宽度。密封中的通道将很容易被检测到。使用每侧5秒作为四面包装的指导(正常呼吸袋可能只要对一侧进行封口,所以只需要1面,如果你的工艺要求需要对呼吸袋的四周进行封口加固,那么需要对四个面的密封性进行确认)。总时间应少于或等于20秒。如果暴露时间过长,染料通过多孔包装的毛细作用会使整个密封区域着色,这会使缺陷检测变得困难。可以使用5倍至20倍放大的光学设备进行详细检查。

11.1.3 Rotate the package as necessary to expose each seal edge to the dye penetrant solution. Inject additional dye as needed to ensure complete edge exposure.

根据需要旋转包装,以使每个密封边缘暴露于染料渗透剂溶液中。如有需要,注入额外的染料以确保完全边缘暴露。

11.2 Method B (Edge Dip Method): 方法B(边缘浸蘸法)

11.2.1 Select a container whose length is long enough to accommodate the longest sealed edge of the package.

选择一个容器,其长度足以容纳包装的最长密封边缘。

11.2.2 Pour enough dye into the container to cover the entire bottom surface to a minimum depth of approximately 3-6mm or 0.125-0.25 in.

倒入足够的染料,以覆盖容器底部整个表面,至大约3-6毫米或0.125-0.25英寸的最小深度。

11.2.2.1 If the package being tested has excessive material beyond the seal, such as a chevron style opening feature, a modification must be made to the package. With a cutting instrument, remove the excessive material along the outside edge of the chevron seal to a distance of approximately 3 mm or 0.125 in. from the seal, taking care not to cut into the seal area. Removal of the excess material will allow the dye solution to come into close proximity to the seal.

如果正在测试的包装在密封处有过多的材料,例如带有V形开口特性的包装,必须对包装进行修改。使用切割工具,沿着V形封边的外侧边缘切除多余材料,距离密封处大约3毫米或0.125英寸,注意不要切入密封区域。去除多余的材料将使染料溶液能够接近密封处。

11.2.3 Lower one of the edges of the package into the dye solution so that it briefly touches the dye along the entire edge of the seal. This needs to be a brief dip process, just long enough to completely wet the edge.

将包装的其中一个边缘浸入染料溶液中,使其沿整个密封边缘短暂接触染料。这需要是一个快速的浸蘸过程,时间只要足以完全湿润边缘。

11.2.4 Remove the package in its dipped orientation, and verify that the entire seal edge has been exposed to the dye solution. Observe the package seal area, through the transparent side, for penetration of the dye solution across the seal width. Use 5 seconds per side max as a guide for a 4 sided package. Total time should be less than or equal to 20 seconds.

以浸蘸的方向取出包装,并确认整个密封边缘已经暴露于染料溶液中。通过透明侧面观察包装的密封区域,查看染料溶液是否穿透了密封宽度。对于四面包装,使用每侧最多5秒作为指导。总时间应少于或等于20秒。

11.2.5 An optical device with 5× to 20x magnification may be used for detailed examination.

可以使用5倍至20倍放大的光学设备进行详细检查。

11.2.6 Repeat edge dip for the remaining seals.

对剩余的密封边缘重复边缘浸蘸过程。

11.3 Method C (Eyedropper Method): 方法C(滴管法)

NoTE 2-This method requires the package to have an unsealed area beyond the outer edge of the seal.

注意2 - 这种方法要求包装在密封的外边缘之外有一个未密封的区域。

11.3.1 Pour dye solution into an open container.

将染料溶液倒入一个开放的容器中。

11.3.2 Using a finger or the end of a paper clip, carefully push back the extended edge of the porous material away from the transparent material.

使用手指或纸夹的末端,小心地将多孔材料的延伸边缘从透明材料处推开。

11.3.3 Insert eyedropper or pipette into the dye solution.

将滴管或移液管插入染料溶液中。

11.3.4 With the transparent side of the package facing the operator, lay a bead of the dye solution along the top edge of the package between the porous and transparent material.

将包装的透明侧面朝向操作者,在包装的顶部边缘,在多孔材料和透明材料之间,排列成一串染料溶液。

11.3.5 For small packages slowly rotate the package, while applying solution until the entire package seal is exposed to the solution. Otherwise, apply solution to one side of the package at a time.

对于小包装,一边慢慢旋转包装,一边涂抹溶液,直到整个包装密封都被溶液暴露。否则,一次只对包装的一侧涂抹溶液。

11.3.6 Observe the package seal area for penetration of the dye solution across the seal width. Use 5 seconds per side max as a guide for a 4 sided package. Total time should be less than or equal to 20 seconds.

观察包装的密封区域是否有染料溶液穿透密封宽度。对于四面包装,使用每侧最多5秒作为指南。总时间应少于或等于20秒。

12. Report报告

12.1 Report the following information:报告以下信息

12.1.1 Complete identification of material being tested, including, but not limited to, lot number and source of material, date, time, location, and operator of test.

被测试材料的完整标识,包括但不限于材料的批号和来源、测试日期、时间、地点和操作员(呼吸袋的不同品牌、型号、封边尺寸等,包括封口机的的配方以及标准操作等均应该在方案中进行科学评估、设计)

12.1.2 Any conditioning of the materials.

材料的所有条件。

12.1.3 A reference to test method performed: Method A, B, and/or C.

执行的测试方法的引用:A方法、B方法和/或C方法。

12.1.4 Identification of the dye penetrant solution if different from that specified in section 5.7.

如果与第5.7节中指定的染料渗透溶液不同,需标识所用溶液

12.1.5 Method of visual inspection; aided or unaided.

视觉检查的方法;辅助或无辅助。

12.1.6 Results:结果

12.1.6.1 Evidence of dye penetration to the opposite side of the seal via a defined channel shall be taken as an indication of the presence of a leakage site.

染料通过规定的通道渗透到密封件的另一侧的证据应视为存在泄漏部位的指示。

12.1.6.2 Evidence of dye penetration through the porous material through general wetting of the surface (wicking) shall not be taken as an indication of the presence of a leakage site.

通过表面普遍润湿(毛细作用)在多孔材料中发现染料渗透的证据,不应被视为存在泄漏点的指示。

12.1.6.3 A qualitative description or sketch of the leakage sites.

对泄漏点的定性描述或草图。

12.1.6.4 Any deviation from standard.

任何对标准的偏差。

13. Precision and Bias精度和偏差

13.1 Injection Method:注射法

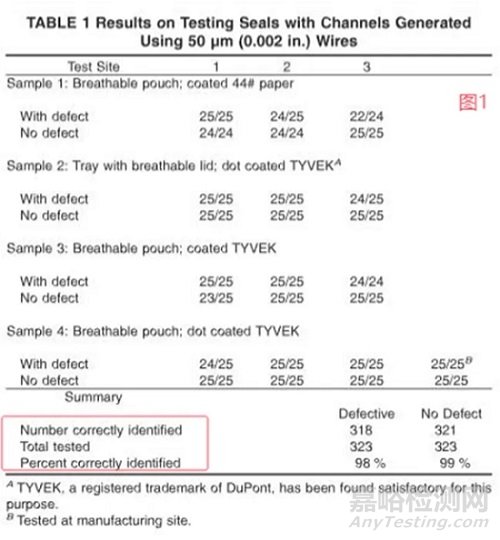

13.1.1 Between June 1997, and March 1998 test packages from four manufacturers were examined using this method by three independent laboratories. Defects were intentionally created in the package seals by placing wires of 50 μm (0.002 in.) diameter in the seal area. When the wires were removed, a channel approximately the size of the wire was created in the seal. For each specimen set, 50 packages were produced. 25 with wire created defects and 25 controls with no artificial defects. The results are shown in Table I as (the number of correctly identified defects) / (the number of test packages).

在1997年6月至1998年3月期间,三个独立的实验室使用这种方法检查了四个制造商的测试包装。通过在密封区域放置直径为50微米(0.002英寸)的钢丝来故意制造缺陷。当钢丝被移除时,在密封处形成了一个大约与钢丝大小相同的通道。对于每组样本,生产了50个包装。其中25个带有钢丝制造的缺陷,25个作为对照组,没有人工缺陷。结果在表1中显示为(正确识别的缺陷数量)/(测试包装的数量)。

13.1.2 The results show that when using the dye penetrant on packages with one side consisting of a porous breathable membrane, there is more than 95 % confidence that channels in package seals will be detected if they are equivalent in size to those made with a 50 μm (0.002 in.) wire. In this test series, significant reductions in test performance (probability of detecting a defect <60 %) were observed with pouches fabricated with film on both surfaces and with indicator dyes other than toluidine blue. Previous testing had shown significantly poorer detection with other wetting agents. These test results are therefore specific for this dye and wetting agent formulation.

13.1.2 结果显示,当在包装的一面使用染料渗透剂,而这一面由多孔透气膜组成时,如果密封处的通道大小与用50微米(0.002英寸)钢丝制造的通道相等,那么有超过95%的把握可以检测到这些通道。在这个测试系列中,用薄膜覆盖两面的袋子以及使用除甲苯胺蓝之外的指示染料时,观察到测试性能显著下降(检测缺陷的概率<60%)。以前的测试显示,使用其他润湿剂的检测效果明显较差。因此,这些测试结果特定于这种染料和润湿剂的配方。

13.1.3 The above P&B statement and Table 1 were generated using Method A only.

以上精度和偏差声明及表1仅使用方法A生成。

13.1.4 Bias—Pass/fail tests have no bias.

偏差—合格/不合格测试没有偏差。

13.2 Edge Dip and Eyedropper Methods:

边缘浸染法和滴注法:

13.2.1 Edge dip and eyedropper Interlaboratory studies of ASTM F1929, Standard Test Method for Detecting Seal Leaks in Porous Medical Packaging by Dye Penetration were conducted in 2012. Of the twelve laboratories that participated, seven tested the edge dip method, and five tested the eyedropper method. Defects were intentionally created by placing wires of 50 μm (0.002 in.) diameter in the seal area. The wires were removed and a channel approximately the size of the wire was created in the seal. Each participant analyzed 50 randomly coded samples (25 produced with channels and 25 without channels) for each of five materials. Every analyst reported results to indicate the presence or absence of a channel. The results were tabulated as the number identified correctly, false positives, and false negatives; the details are given in RR:F02-10324.

2012年对ASTM F1929标准测试方法进行了边缘浸蘸法和滴管法的实验室间研究,该标准测试方法是通过染料渗透检测多孔医用包装的密封泄漏。参与的十二个实验室中,有七个实验室测试了边缘浸蘸法,五个实验室测试了滴管法。通过在密封区域放置直径为50微米(0.002英寸)的钢丝来故意制造缺陷。钢丝被移除后,在密封处形成了大约与钢丝大小相同的通道。每个参与者分析了五种材料的50个随机编码样本(25个带有通道,25个不带通道)。每位分析师报告了结果,以指明通道的存在或不存在。结果被记录为正确识别的数量、误报和漏报;详细信息见RR:F02-10324。

13.2.2 When combining the edge dip data population of all labs, the results show that this method provides the correct response of detecting channels created by a 50 μm wire in seals 95% of the time. The 95% confidence interval is 93.8% to 96.0 %. The results of correctly identified, false positives, and false negatives are shown in Tables 2-4.

将所有实验室的边缘浸蘸数据汇总后,结果显示这种方法在95%的情况下正确响应了由50微米钢丝在密封中创建的通道。95%的置信区间为93.8%至96.0%。正确识别、误报和漏报的结果分别显示在图2-4中。

13.2.3 When combining the eyedropper data population of all labs, the results show that this method provides the correct response of detecting channels created by a 50 μm wire in seals 99 % of the time. The 95 % confidence interval is 97.7% to 99.1%. The results of correctly identified, false positives, and false negatives are shown in Tables 5-7.

将所有实验室的滴管数据汇总后,结果显示这种方法在99%的情况下正确响应了由50微米钢丝在密封中创建的通道。95%的置信区间为97.7%至99.1%。正确识别、误报和漏报的结果分别显示在图5-7中。

13.2.4 Bias—Pass/fail tests have no bias.

偏差—合格/不合格测试没有偏差。

13.2.5 The materials tested were identified as:

测试的材料被识别为:

Coated Tyvek, Hot Melt Adh., /Rigid Packaging Substrate.

涂层Tyvek,热熔胶,/硬质包装基材。

Uncoated Tyvek, No Adh., /Flexible Packaging Substrate.

未涂层Tyvek,无胶,/柔性包装基材。

Coated Tyvek, Hot Melt Adh., /Flexible Packaging Substrate.

涂层Tyvek,热熔胶,/柔性包装基材。

Coated Tyvek, Water-Based Adh., /Flexible Packaging Substrate.

涂层Tyvek,水基胶,/柔性包装基材。

Coated Paper, Water-Based Adh., /Flexible Packaging Substrate.

涂层纸,水基胶,/柔性包装基材。

14. Keywords关键词

14.1 dye penetrant; edge dip; eyedropper; flexible packaging

染料渗透剂;边缘浸染;滴注;柔性包装

APPENDIX附录

(Nonmandatory Information)非强制信息

X1. FALSE POSITIVE GUIDANCE假阳性指导

X1.1 Wicking: The dye solution used for this testing is very aggressive. It will wick along the fibers of the Tyvek and other porous materials quickly. This will appear to be a partial penetration of the seal area, and can be misinterpreted as a test failure. Dissimilarly, a channel defect in the seal provides a path across the entire seal width and will be evident almost immediately after exposure to the dye solution. This can be readily distinguished from the wicking phenomenon, as capillary action in a channel is much faster than wicking. The correct exposure time is important in distinguishing the difference between wicking and a channel. 5 seconds is all the time required, since channel penetration is typically noticed within the first few seconds of exposure. If dye solution exposure is for 20 seconds, wicking can be severe. 20 seconds is the intended exposure time for the whole package, i.e., 5 seconds x 4 sides = 20 seconds.

X1.1 毛细现象:用于此测试的染料溶液非常活跃。它会迅速沿着Tyvek和其他多孔材料的纤维进行毛细渗透。这看起来像是密封区域的部分渗透,可能会被误解为测试失败。不同地,密封中的通道缺陷提供了一条穿过整个密封宽度的路径,并且在接触染料溶液后几乎立即显现出来。这可以很容易地区分毛细现象,因为通道中的毛细作用速度远远快于毛细渗透。正确的曝光时间对于区分毛细渗透和通道至关重要。通常只需要5秒钟,因为通道渗透通常在接触的最初几秒钟内就能被注意到。如果染料溶液的曝光时间是20秒,毛细渗透可能会很严重。20秒是整个包装的预期曝光时间,即5秒 x 4面 = 20秒。

X1.2 Oxidative Sterilization: Oxidative sterilization processes can change the hydrostatic head of some porous materials. This change to the surface tension can cause false positive results due to excessive wicking. Before using liquid-based integrity testing, it is important to evaluate the sterilization effects on the hydrostatic head property of the materials.

X1.2 氧化灭菌:氧化灭菌过程可能会改变一些多孔材料的静压。这种对表面张力的改变可能会导致由于过度毛细作用而产生假阳性结果。在使用基于液体的完整性测试之前,评估灭菌对材料静水压头属性的影响是重要的。

X1.3 Bending/Folding: A false-positive can occur when a flexible porous material is bent, folded, or creased. The folding causes internal sheet separation of the porous web. This can happen when a pouch is folded to fit into a shelf container or is folded or bent during distribution stress testing. The folding of porous barrier materials is not recommended but is often ignored or difficult to avoid. Sheet separation has been observed in all types of porous sheet materials. Porous sheets can separate internally because the exterior surfaces are less flexible than the interior. The bending forces can result in the yielding of the interior fibers that hold the sheet together. The tighter the bend the greater forces become until the load becomes excessive and the fiber structure holding the sheet together will separate and compress on one side of the bend, expand on the other side creating a gap or channel between internal fibers at the bend. When the sheet is unbent or flattened out again, there will still be a less dense area or gap formed in the interior of the sheet. These areas in the porous sheet are separations within the softer inner layer between the more rigid outer surfaces. The original mass of the fibers is still there, only the bulk density has decreased. During dye testing, the dye will wick through the surface layer and penetrate to the separation site. At that point, the dye finds this path of least resistance and quickly migrates to the edge of the sheet creating a channel-like appearance.

X1.3 弯曲/折叠:当柔性多孔材料被弯曲、折叠或出现折痕时,可能会发生假阳性。折叠会导致多孔网状材料的内部层分离。这可能发生在将袋子折叠以适应货架容器内,或在分发过程中的压力测试中被折叠或弯曲。不推荐折叠多孔屏障材料,但这种做法经常被忽视或难以避免。在所有类型的多孔片材中都观察到了层分离。多孔片材可以因为外部表面比内部更不灵活而内部分离。弯曲力可能导致内部纤维发生屈服,这些纤维将片材固定在一起。弯曲越紧,力就越大,直到负荷过大,固定片材的纤维结构会在弯曲的一侧分离并压缩,在另一侧扩展,形成弯曲处内部纤维之间的间隙或通道。当片材再次展平或去弯时,片材内部仍然会形成一个密度较小的区域或间隙。这些多孔片材中的区域是在较软的内层与较硬的外表面之间的分离。纤维的原始质量仍然存在,只是整体密度降低了。在染料测试期间,染料会通过表层毛细渗透并穿透到分离处。在这一点上,染料找到了阻力最小的路径,并迅速迁移到片材边缘,形成类似通道的外观。

结论:对于常见的封口机验证,如果仅是对封边进行外观检查,大概率是不够的,审计会面临比较大的挑战。

来源:GMP的那些事